Product Description

Product Description

Regular nonferrous metals that we engaged in include copper, iron (Japanese standard SUM24L, SUM22; American standard 12L14, 12L15), aluminum (6060, 6063, LY12, etc.), stainless steel (SUS303, SUS316), stainless iron (SUS416, SUS430)

Regular products that we manufactured:

1. spare parts for consumer electonics:

alloy housing, alloy stands, pin, inserts, terminals, shafts, specialty screws, stand-offs, valves, etc

2. auto spare parts/motorcycle parts/new energy vehicle parts

motorcycle clutch parts, wheel rim, etc

3. industrial machine spare parts

heavy industrial machine spare parts like foundations and sleeves.

If you have any parts to be made, please feel free to contact us.

Detailed Photos

Product Parameters

| Sample profile | Weight: Customized |

| Available materials | Steel, Aluminum, Alloy ,Brass, Copper, Bronze, etc |

| Software/format | PRO/E, Auto CAD, CHINAMFG works, IGS, UG, CAD/CAM/CAE |

| Tolerance | (±5um) or as customer required |

| Test equipment | Measurement instrument, projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin guage etc. |

| Processing | CNC turning, milling, drilling, auto lathe, tapping, bushing, surface treatment, anodized, casting ,injection,3D printing,etc. |

| Application | Mechinery/Education/Artificial Intellegence/Construction/Industrial/Electrical Products/Medical Products/New Energy Vehicals/Aerospace/Defense |

| MOQ | 1-10 pcs |

| QC System | 100% inspection before shipment |

| Service | OEM/ODM/Customized/Design |

| Delivery date | 7-30days |

| Package | Packaged by Carton Box or as Your Request |

Certifications

Packaging & Shipping

Company Profile

HangZhou Ohm Industrial Co., Ltd was established in 2018, specializing in the manufacuring and exporting non-ferrous metal machinery parts. Including product designing, sampling, confirming, manufacturing and shipping, we can provide you 1 stop service for any metal parts for uses like robotics, education, construction, industrial automation, consumer electronics, aerospace and defense, new energy vehicle, medical and detal, etc. All of our production is carried out in compliance with international quality-control standards and our products enjoy a good reputation both at home and abroad. We have been adhering to the policy of the best service, high quality, fast delivery. We also meet customer needs to the greatest extent. Our factory covers an area of 5000 square meters, and owes 200pcs high-precision machine tools and archived annual output of more than 30 million US dollars in 2571. We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefits. We support your customization, if you have any needs, please feel free to contact us.

Machine Services

Our Advantages

FAQ

Q1: Where can I get product or price information?

A1: Send us an inquiry in this page or e-mail, we will contact you after CHINAMFG receipt of your mail.

Q2: Do you provide samples? Is it free or extra?

A2: Yes, we can provide samples. We will charge you based on sample processing and the fee will be returned to your bulk order.

Q3: How soon can I get products?

A3: Samples are generally 3-7 days; bulk orders are 10-25 days, depending on the quantity and parts requirements.

Q4: I don’t have any files for spare part that I want to purchase. I just have real samples. Can you produce it in large quantiity?

A4: Yes. Our professional engineer can draw CAD file CHINAMFG your sample. But the tolerance is lower than the 1 that made by orignal drawings.

Q5: Why you quotation is much lower than my regular suppliers? Is it the same quality?

A5: Because the cost of custom parts is quoted by the time of machine running and the technician operating. Our engineer has more than 20 years transforming the relevant drawings into simple machine codes, which can be optimized tremendously.

Q6: How do you guarantee the quality of your products?

A6: We can provide all kinds of testing certificates. And we will take 100% inspection during production.

Q7: What is your after-sale service?

A7: If there is any question, please provide photos or test reports, we will handle it for you in a timely manner.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO9001, UV |

| Standard: | DIN, ASTM, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Stainless Steel |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Customization: |

Available

| Customized Request |

|---|

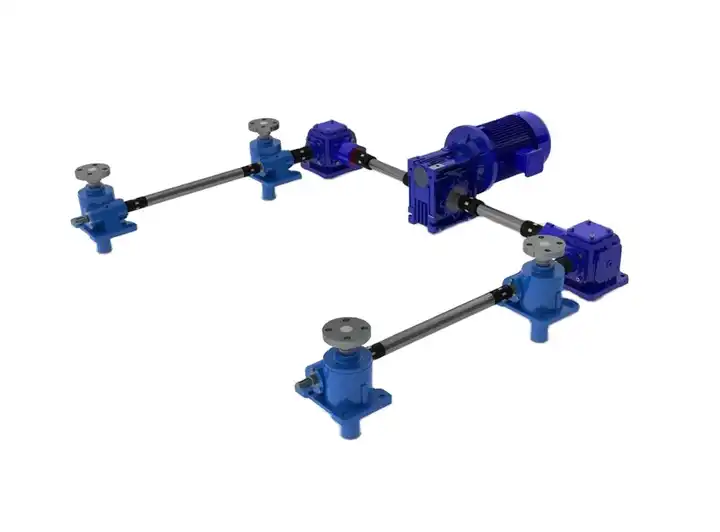

How do screw jacks impact the overall cost-effectiveness of industrial processes?

Screw jacks have a significant impact on the overall cost-effectiveness of industrial processes. They offer several advantages that contribute to cost savings, improved efficiency, and increased productivity. Here’s how screw jacks impact the cost-effectiveness of industrial processes:

- Precision and Accuracy: Screw jacks provide precise and accurate positioning, alignment, and movement of components. This precision reduces errors, rework, and scrap, resulting in higher product quality and lower production costs. Accurate positioning also improves the efficiency of assembly, reducing the time required for adjustments and alignments.

- Flexibility and Adaptability: Screw jacks are versatile and can be customized to meet specific requirements. They can be easily integrated into existing systems or machinery, allowing for cost-effective modifications or upgrades. Their adaptability enables the optimization of processes, reducing the need for expensive equipment replacements.

- Load Handling Capacity: Screw jacks have high load handling capacities, allowing them to support heavy loads. This eliminates the need for additional equipment or specialized machinery, reducing capital investment and operational costs. The ability to handle substantial loads efficiently also improves productivity and throughput.

- Maintenance and Durability: Screw jacks are designed for durability and require minimal maintenance. Their robust construction and use of materials that withstand harsh environments contribute to their long service life. Reduced maintenance requirements result in lower maintenance costs and less downtime, leading to increased overall productivity.

- Energy Efficiency: Screw jacks offer energy-efficient operation. They consume power only during movement or adjustment and require no power when holding a position. This energy efficiency reduces operational costs and contributes to a greener and more sustainable approach to industrial processes.

- Safety and Operator Ergonomics: Screw jacks can improve safety and operator ergonomics in industrial processes. They allow for controlled and precise movement, reducing the risk of accidents or injuries. Moreover, screw jacks can be designed to facilitate ergonomic positioning of workpieces, reducing strain on operators and enhancing their productivity.

- Reliability and Longevity: Screw jacks are known for their reliability and long service life. Their robust construction and use of high-quality materials ensure dependable performance even in demanding industrial environments. The reduced need for frequent replacements or repairs contributes to cost savings in the long run.

By offering precision, flexibility, efficiency, durability, and safety, screw jacks positively impact the cost-effectiveness of industrial processes. They optimize productivity, reduce operational expenses, and enhance the overall efficiency of manufacturing, assembly, and material handling processes.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

How do screw jacks ensure stable and controlled movement of loads?

Screw jacks are designed to ensure stable and controlled movement of loads through various mechanisms and features. These mechanisms work together to provide stability, precision, and safety during load handling. Here’s how screw jacks achieve stable and controlled movement:

- Self-Locking Mechanism: Screw jacks are equipped with self-locking mechanisms that prevent the load from lowering or descending when the screw is not being rotated. This mechanism ensures that the load remains stable and stationary even in the absence of an external driving force. The self-locking feature is achieved through the thread design and the friction between the screw and the nut. It provides inherent stability and eliminates the need for additional braking or locking mechanisms.

- High Mechanical Advantage: Screw jacks offer a high mechanical advantage, allowing for controlled movement of heavy loads with relatively low input force. The mechanical advantage is determined by the pitch of the screw and the size of the input device. By increasing the pitch or using a larger input device, the mechanical advantage can be enhanced, enabling precise and controlled movement even with substantial loads.

- Precision Thread Design: The threads of the screw and the nut in screw jacks are precision-designed to minimize backlash and play, ensuring smooth and accurate movement. The thread design influences the amount of axial movement achieved per rotation of the screw, directly impacting the precision of load positioning. By using high-quality threads and incorporating anti-backlash features, screw jacks maintain stability and control during load movement.

- Limit Switches and Position Sensors: Screw jacks can be equipped with limit switches or position sensors to provide accurate position feedback and prevent overtravel or exceedance of specified limits. These devices ensure that the load stops at the desired position and prevent any unsafe or unintended movement. Limit switches and position sensors enhance the control and safety of screw jack systems.

- Additional Safety Features: Screw jacks may incorporate additional safety features to ensure stable and controlled movement. These features can include overload protection mechanisms that prevent excessive loads from damaging the screw jack or the load-bearing structure. Emergency stop options or mechanical brakes may also be included to halt the movement in case of emergencies or power failure.

- Sturdy Construction: Screw jacks are built with robust materials and construction to withstand heavy loads and provide stability during operation. The components are designed to handle the forces exerted during load movement and maintain structural integrity. Sturdy construction ensures that the screw jack can reliably handle the load without compromising stability or control.

By incorporating self-locking mechanisms, high mechanical advantage, precision thread design, limit switches, position sensors, additional safety features, and sturdy construction, screw jacks ensure stable and controlled movement of loads. These features work together to provide precise positioning, prevent unintended movement, and enhance the safety of load handling operations.

editor by CX 2024-04-12