Product Description

Product details

Features

- For plain shafts

- Single seal

- Unbalanced

- Rotating conical spring

- Dependent on direction of rotation

Advantages

- Universal application opportunities

- Insensitive to low solids content

- No damage of the shaft by set screws

- Large choice of materials

- Short installation lengths possible (G16)

- Variants with shrink-fitted seal face available

Operating range

Shaft diameter:

d1 = 6 … 80 mm (0,24″ … 3,15″)

Pressure: p1 = 10 bar (145 PSI)

Temperature:

t = -20 °C … +140 °C (-4 °F … +355 °F)

Sliding velocity: vg = 15 m/s (50 ft/s)

Axial movement: ±1.0 mm

Materials

Seal face: Special cast CrMo steel (S)

Seat G9: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

Recommended applications

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Building services industry

- Food and beverage industry

- Sugar industry

- Low solids content media

- Water and sewage water pumps

- Submersible pumps

- Chemical standard pumps

- Eccentric screw pumps

- Cooling water pumps

- Basic sterile applications

| AK-M3N/AK-M3 Dimensions(mm) | |||||||||

| Size | d | D3 | D6 | D7 | D8 | L3* | L31* | L4 | L8 |

| 10 | 10 | 19 | 17 | 21 | 3 | 15.5 | 15.5 | 10.0 | 17.5 |

| 12 | 12 | 21 | 19 | 23 | 3 | 16.0 | 15.5 | 10.0 | 17.5 |

| 14 | 14 | 23 | 21 | 25 | 3 | 16.5 | 15.5 | 10.0 | 17.5 |

| 16 | 16 | 26 | 23 | 27 | 3 | 18.0 | 17.5 | 10.0 | 17.5 |

| 18 | 18 | 29 | 27 | 33 | 3 | 19.5 | 18.5 | 11.5 | 19.5 |

| 20 | 20 | 31 | 29 | 35 | 3 | 22.0 | 20.0 | 11.5 | 19.5 |

| 22 | 22 | 33 | 31 | 37 | 3 | 21.5 | 21.5 | 11.5 | 19.5 |

| 24 | 24 | 35 | 33 | 39 | 3 | 23.5 | 23.0 | 11.5 | 19.5 |

| 25 | 25 | 36 | 34 | 40 | 3 | 26.5 | 24.5 | 11.5 | 19.5 |

| 28 | 28 | 40 | 37 | 43 | 3 | 26.5 | 24.5 | 11.5 | 19.5 |

| 30 | 30 | 43 | 39 | 45 | 3 | 26.5 | 24.5 | 11.5 | 19.5 |

| 32 | 32 | 46 | 42 | 48 | 3 | 28.5 | 28.0 | 11.5 | 19.5 |

| 33 | 33 | 47 | 42 | 48 | 3 | 28.5 | – | 11.5 | 19.5 |

| 35 | 35 | 49 | 44 | 50 | 3 | 28.5 | 28.0 | 11.5 | 19.5 |

| 38 | 38 | 53 | 49 | 56 | 4 | 33.5 | 21.0 | 14.0 | 22.0 |

| 40 | 40 | 56 | 51 | 58 | 4 | 36.0 | 34.0 | 14.0 | 22.0 |

| 43 | 43 | 59 | 54 | 61 | 4 | 38.5 | – | 14.0 | 22.0 |

| 45 | 45 | 61 | 56 | 63 | 4 | 39.5 | 36.5 | 14.0 | 22.0 |

| 48 | 48 | 64 | 59 | 66 | 4 | 46.0 | 42.0 | 14.0 | 22.0 |

| 50 | 50 | 66 | 62 | 70 | 4 | 45.0 | 43.0 | 15.0 | 23.0 |

| 53 | 53 | 69 | 65 | 73 | 4 | 47.0 | – | 15.0 | 23.0 |

| 55 | 55 | 71 | 67 | 75 | 4 | 49.0 | 47.0 | 15.0 | 23.0 |

| 58 | 58 | 76 | 70 | 78 | 4 | 55.0 | 50.0 | 15.0 | 23.0 |

| 60 | 60 | 78 | 72 | 80 | 4 | 55.0 | 51.0 | 15.0 | 23.0 |

| 63 | 63 | 83 | 75 | 83 | 4 | 55.0 | – | 15.0 | 23.0 |

| 65 | 65 | 84 | 77 | 85 | 4 | 55.0 | 52.0 | 15.0 | 23.0 |

| 68 | 68 | 88 | 81 | 90 | 4 | 55.0 | 53.0 | 18.0 | 26.0 |

| 70 | 70 | 90 | 83 | 92 | 4 | 57.0 | 54.0 | 18.0 | 26.0 |

| 75 | 75 | 98 | 88 | 97 | 4 | 62.0 | 55.0 | 18.0 | 26.0 |

| 80 | 80 | 100 | 95 | 105 | 4 | 61.8 | 58.0 | 18.2 | 26.2 |

| *L3 Valid for AK-M3N;L31 valid for AK-M3 | |||||||||

Product photos:

Riscky Li

Website: http://akman2006 /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Structure: | Single End |

|---|---|

| Pressure: | High Pressure Mechanical Seals |

| Speed: | High-Speed Mechanical Seal |

| Temperature: | High Temperature Mechanical Seal |

| Standard: | Standard |

| Balance: | Unbalanced |

| Customization: |

Available

| Customized Request |

|---|

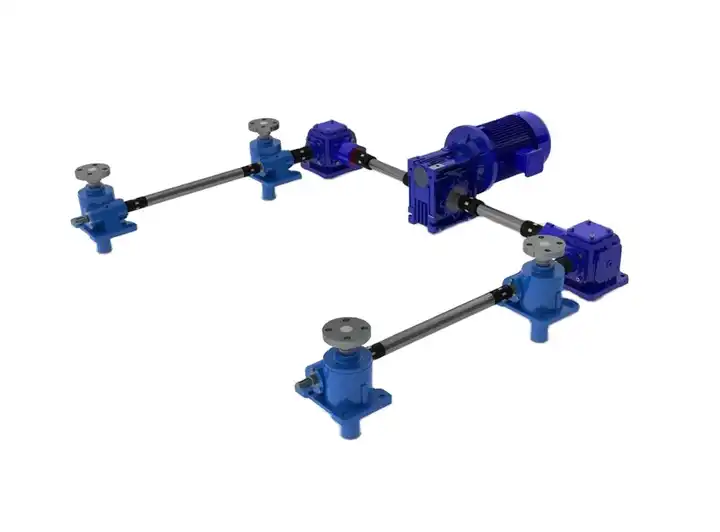

Can screw jacks be adapted for use in both indoor and outdoor environments?

Yes, screw jacks can be adapted for use in both indoor and outdoor environments. They are versatile mechanical devices that can be designed and manufactured to withstand various environmental conditions. Here’s how screw jacks can be adapted for both indoor and outdoor use:

- Enclosure and Sealing: When screw jacks are intended for outdoor use, they can be equipped with enclosures and sealing mechanisms to protect the internal components from environmental factors such as moisture, dust, or debris. These enclosures are typically made from durable materials like stainless steel or corrosion-resistant coatings to ensure long-term protection.

- Corrosion Resistance: Outdoor environments often expose equipment to corrosive elements. To address this, screw jacks can be manufactured with corrosion-resistant materials or coatings. Stainless steel or zinc plating are commonly used to enhance the corrosion resistance of screw jacks, making them suitable for outdoor applications where exposure to moisture, humidity, or chemicals is expected.

- Weatherproofing: Screw jacks can be designed with weatherproofing features to resist environmental conditions such as rain, snow, or extreme temperatures. This may include seals, gaskets, or protective covers that prevent water or debris from entering the internal components, ensuring reliable operation in outdoor environments.

- UV Resistance: Outdoor applications often expose equipment to ultraviolet (UV) radiation from sunlight. Screw jacks can be manufactured using materials that are UV-resistant or incorporate UV-protective coatings. This helps prevent degradation or discoloration of the components due to prolonged exposure to sunlight.

- Temperature Considerations: Screw jacks can be designed to operate within a wide temperature range to accommodate diverse outdoor environments. Specialized lubricants and materials with high-temperature stability can be used to ensure proper functioning and prevent damage or degradation in extreme temperature conditions.

- IP Ratings: In certain applications, screw jacks may require specific Ingress Protection (IP) ratings to ensure their suitability for outdoor use. IP ratings indicate the level of protection against solids and liquids. Screw jacks can be manufactured with specific IP ratings to meet the environmental requirements of different outdoor applications.

By incorporating these adaptations, screw jacks can be effectively used in both indoor and outdoor environments. Whether it’s in manufacturing facilities, construction sites, or outdoor maintenance tasks, screw jacks provide reliable performance and can withstand the challenges posed by various environmental conditions.

Can screw jacks be used for both light-duty and heavy-duty applications?

Yes, screw jacks are versatile mechanical devices that can be used for both light-duty and heavy-duty applications. Their design and construction allow them to handle a wide range of loads, making them suitable for various industrial, commercial, and residential tasks. Here’s how screw jacks are used in both light-duty and heavy-duty applications:

- Light-Duty Applications: Screw jacks find application in numerous light-duty tasks where precise positioning, lifting, or adjustment is required. Examples of light-duty applications include:

- Workbenches and assembly stations: Screw jacks can be employed to adjust the height of workbenches or assembly stations, allowing operators to work at comfortable levels.

- Stage and theater equipment: Screw jacks are used to raise or lower stage platforms, lighting fixtures, or props, allowing for easy setup and adjustments during performances.

- Medical and healthcare equipment: Screw jacks are utilized in medical beds, examination tables, or dental chairs to enable height adjustments for patient comfort and medical procedures.

- Optical and laboratory equipment: Screw jacks provide precise vertical positioning in optical systems, microscopes, or laboratory setups, ensuring accurate alignment and focus.

- Residential applications: Screw jacks can be used in home applications, such as adjustable tables, ergonomic furniture, or lifting mechanisms for storage units.

- Heavy-Duty Applications: Screw jacks are also capable of handling heavy-duty applications that involve substantial loads and demanding conditions. Examples of heavy-duty applications include:

- Industrial machinery: Screw jacks are utilized in various industrial machinery, including presses, injection molding machines, or material handling equipment, to provide precise control and lifting capabilities.

- Construction and infrastructure projects: Screw jacks are employed in construction tasks, such as formwork systems, scaffolding, or temporary structures, for lifting, leveling, or supporting heavy loads.

- Transportation and automotive: Screw jacks find application in automotive lifts, vehicle maintenance equipment, or cargo handling systems, enabling the lifting and positioning of heavy vehicles or loads.

- Shipbuilding and offshore industries: Screw jacks are used in shipbuilding and offshore applications for tasks such as aligning sections, adjusting propeller pitch, or lifting heavy components during construction or maintenance.

- Mining and heavy equipment: Screw jacks are utilized in mining machinery, cranes, or heavy equipment for load positioning, maintenance, or stabilization.

It’s important to note that the specific design, size, and load capacity of the screw jack should be matched to the requirements of the application. Manufacturers provide a wide range of screw jack models with varying load capacities, travel distances, and configurations to accommodate both light-duty and heavy-duty applications. Proper selection and installation of the screw jack ensure optimal performance and safety in diverse tasks.

Which industries and sectors commonly rely on screw jacks for their operations?

Screw jacks find applications in various industries and sectors where lifting heavy loads, adjusting height, or precise positioning is required. Here are some of the industries and sectors that commonly rely on screw jacks for their operations:

- Manufacturing: Screw jacks are extensively used in manufacturing industries for tasks such as lifting and positioning heavy equipment, adjusting assembly line heights, and aligning components during production processes.

- Construction: The construction industry utilizes screw jacks for tasks like lifting and stabilizing structural elements during building construction, adjusting formwork and scaffolding heights, and positioning heavy machinery or materials.

- Automotive: In the automotive sector, screw jacks are employed for lifting vehicles during maintenance and repairs, adjusting conveyor heights in assembly lines, and positioning components during manufacturing processes.

- Transportation and Logistics: Screw jacks are used in transportation and logistics for tasks such as adjusting loading dock heights, raising or lowering platforms on trucks or trailers, and positioning cargo handling equipment.

- Entertainment and Events: The entertainment and events industry relies on screw jacks for stage setups, lifting and adjusting lighting equipment, raising or lowering platforms for performers, and creating dynamic stage effects.

- Aerospace and Defense: Screw jacks are utilized in the aerospace and defense sectors for applications such as adjusting heights of launch platforms, positioning aircraft components during assembly, and operating heavy-duty doors or hatches.

- Material Handling and Warehousing: Screw jacks are found in material handling and warehousing operations for tasks like adjusting conveyor heights, lifting heavy pallets or containers, and positioning racks or shelves.

- Mining and Heavy Machinery: The mining industry and sectors involving heavy machinery utilize screw jacks for lifting and positioning equipment, adjusting conveyor heights, and supporting heavy loads in various mining operations.

- Energy and Utilities: Screw jacks are employed in energy and utility sectors for tasks such as adjusting heights of solar panels or wind turbines, raising or lowering equipment in power plants, and positioning components in utility infrastructure.

- Medical and Rehabilitation: In the medical and rehabilitation fields, screw jacks are used for height adjustment of medical beds, positioning of imaging equipment, and providing adjustable support systems for patients.

This list is not exhaustive, and screw jacks may find applications in other industries and sectors beyond those mentioned. The versatility, load capacity, and precise control offered by screw jacks make them valuable tools in a wide range of operations requiring lifting, adjusting, or positioning heavy loads.

editor by CX 2024-03-28