Product Description

Key attributes

Other attributes

Warranty

1.5 years

Applicable Industries

Building Material Shops, Manufacturing Plant, Energy & Mining

Weight (KG)

1

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

New Product 2571

Warranty of core components

1 Year

Core Components

Gear

Material

stainless steel 304, stainless steel 316, 42CrMo, 17CrNiMo, 45steel, 40Cr

Place of Origin

ZheJiang , China

Condition

New

Brand Name

HangZhou

China shaft manufacturer custom chrome steel shaft eccentric shaft

Product Name

Customized forging Steel large Inner tooth Gear Ring

Application

Industry/Gearbox/ Transmission Parts

Size

Customer’s Drawing

Processing

Hobbing/Milling/Shapping

Standard

DIN/GB/AISI

Surface treatment

Polishing/Grinding/ Painting/Anti Rust Oil

Heat Teatment

QT/Hardening/Carburizing

Blank

Forging or Casting as per drawing.

Quality Control

Nondestructive Testing (UT/MT/RT/PT)

Certificate

ISO9001

Packaging and delivery

Packaging Details

1.Wooden box with fumigation

2.Wooden Fram with waterproof cloth

Port

ZheJiang or HangZhou Port

attribute-list

Supply Ability

50000 Piece/Pieces per Year

Lead time

| Quantity (pieces) | 1 – 10 | > 10 |

| Lead time (days) | 45 | To be negotiated |

Production Process

We can produce various specifications of gear, meanwhile, we can also provide gear blanks.

We have a full set of production processes and testing instruments for forging, heat treatment and machining.

We have 5 medium frequency furnaces and 5 electric slag heavy furnaces, which can produce 1 ton-18 tons of various types of alloy steel, with an annual capacity of 10,000 tons. The main characteristics of electroslag remelting are that it can flexibly produce various types of special steel in size and batch, with pure composition, uniform and dense crystal organization.

Natural gas digital display computer temperature control heating CZPT can accurately control the heating temperature of raw materials.

800T fast forging machine can quickly forge products, 3150T and 5000T oil press can forge heavy-duty axle products. They can guarantee the forging ratio required by the product, and ensure a good metallographic structure.

More than 20 digital display resistance furnaces can be used fot normalizing, quenching and tempering products, at the same time, there are induction quenching and carburization process, so as to ensure the mechanical performance requirements of the gear

We have a number of , HOFLER and other gear rolling machine, inner tooth ring milling machine, gear insertion machine, gear grinding machine and car milling CZPT center and other gear processing equipment.

TS regards Quality as the essential part of our business success. Based on your requirements, we have raw material in-coming inspection, process control and pre-shipment inspection. With advanced test equipments such as spectrometer, CMM, tensile strength tester, microscope, hardness tester, etc, TS is CZPT to apply sufficient chemical and physical inspection. According to your request, we are also capable to do X-Ray, Magnetic Testing, Ultrasonic Testing and liquid Penetrant Examination.

PRODUCT PACKAGING

OUR WORKSHOPS

COOPERATIVE BRAND

Product Packaging

Product PackaPRging

| Material: | Steel |

|---|---|

| Load: | Drive Shaft |

| Appearance Shape: | Steel |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

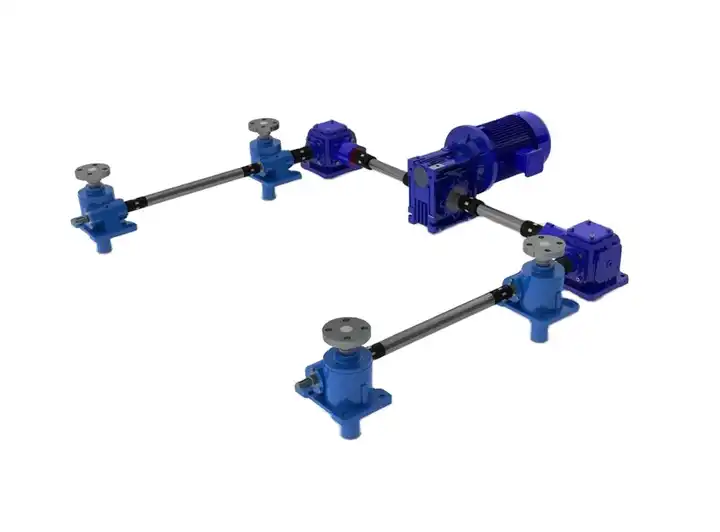

How do screw jacks impact the overall cost-effectiveness of industrial processes?

Screw jacks have a significant impact on the overall cost-effectiveness of industrial processes. They offer several advantages that contribute to cost savings, improved efficiency, and increased productivity. Here’s how screw jacks impact the cost-effectiveness of industrial processes:

- Precision and Accuracy: Screw jacks provide precise and accurate positioning, alignment, and movement of components. This precision reduces errors, rework, and scrap, resulting in higher product quality and lower production costs. Accurate positioning also improves the efficiency of assembly, reducing the time required for adjustments and alignments.

- Flexibility and Adaptability: Screw jacks are versatile and can be customized to meet specific requirements. They can be easily integrated into existing systems or machinery, allowing for cost-effective modifications or upgrades. Their adaptability enables the optimization of processes, reducing the need for expensive equipment replacements.

- Load Handling Capacity: Screw jacks have high load handling capacities, allowing them to support heavy loads. This eliminates the need for additional equipment or specialized machinery, reducing capital investment and operational costs. The ability to handle substantial loads efficiently also improves productivity and throughput.

- Maintenance and Durability: Screw jacks are designed for durability and require minimal maintenance. Their robust construction and use of materials that withstand harsh environments contribute to their long service life. Reduced maintenance requirements result in lower maintenance costs and less downtime, leading to increased overall productivity.

- Energy Efficiency: Screw jacks offer energy-efficient operation. They consume power only during movement or adjustment and require no power when holding a position. This energy efficiency reduces operational costs and contributes to a greener and more sustainable approach to industrial processes.

- Safety and Operator Ergonomics: Screw jacks can improve safety and operator ergonomics in industrial processes. They allow for controlled and precise movement, reducing the risk of accidents or injuries. Moreover, screw jacks can be designed to facilitate ergonomic positioning of workpieces, reducing strain on operators and enhancing their productivity.

- Reliability and Longevity: Screw jacks are known for their reliability and long service life. Their robust construction and use of high-quality materials ensure dependable performance even in demanding industrial environments. The reduced need for frequent replacements or repairs contributes to cost savings in the long run.

By offering precision, flexibility, efficiency, durability, and safety, screw jacks positively impact the cost-effectiveness of industrial processes. They optimize productivity, reduce operational expenses, and enhance the overall efficiency of manufacturing, assembly, and material handling processes.

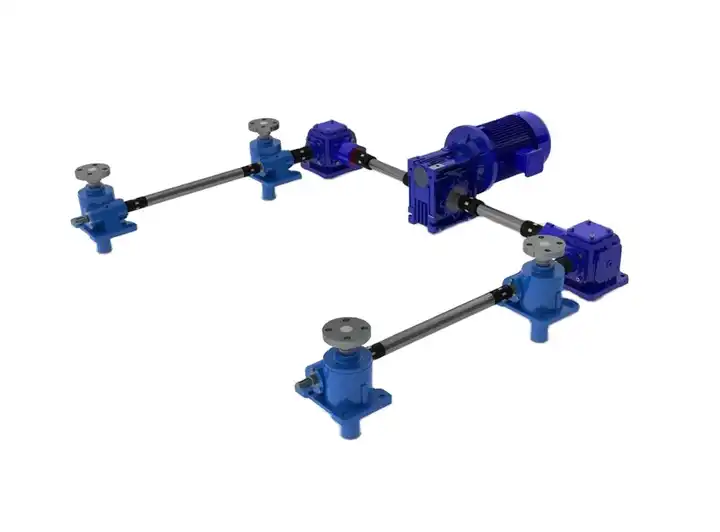

Can screw jacks be used for both light-duty and heavy-duty applications?

Yes, screw jacks are versatile mechanical devices that can be used for both light-duty and heavy-duty applications. Their design and construction allow them to handle a wide range of loads, making them suitable for various industrial, commercial, and residential tasks. Here’s how screw jacks are used in both light-duty and heavy-duty applications:

- Light-Duty Applications: Screw jacks find application in numerous light-duty tasks where precise positioning, lifting, or adjustment is required. Examples of light-duty applications include:

- Workbenches and assembly stations: Screw jacks can be employed to adjust the height of workbenches or assembly stations, allowing operators to work at comfortable levels.

- Stage and theater equipment: Screw jacks are used to raise or lower stage platforms, lighting fixtures, or props, allowing for easy setup and adjustments during performances.

- Medical and healthcare equipment: Screw jacks are utilized in medical beds, examination tables, or dental chairs to enable height adjustments for patient comfort and medical procedures.

- Optical and laboratory equipment: Screw jacks provide precise vertical positioning in optical systems, microscopes, or laboratory setups, ensuring accurate alignment and focus.

- Residential applications: Screw jacks can be used in home applications, such as adjustable tables, ergonomic furniture, or lifting mechanisms for storage units.

- Heavy-Duty Applications: Screw jacks are also capable of handling heavy-duty applications that involve substantial loads and demanding conditions. Examples of heavy-duty applications include:

- Industrial machinery: Screw jacks are utilized in various industrial machinery, including presses, injection molding machines, or material handling equipment, to provide precise control and lifting capabilities.

- Construction and infrastructure projects: Screw jacks are employed in construction tasks, such as formwork systems, scaffolding, or temporary structures, for lifting, leveling, or supporting heavy loads.

- Transportation and automotive: Screw jacks find application in automotive lifts, vehicle maintenance equipment, or cargo handling systems, enabling the lifting and positioning of heavy vehicles or loads.

- Shipbuilding and offshore industries: Screw jacks are used in shipbuilding and offshore applications for tasks such as aligning sections, adjusting propeller pitch, or lifting heavy components during construction or maintenance.

- Mining and heavy equipment: Screw jacks are utilized in mining machinery, cranes, or heavy equipment for load positioning, maintenance, or stabilization.

It’s important to note that the specific design, size, and load capacity of the screw jack should be matched to the requirements of the application. Manufacturers provide a wide range of screw jack models with varying load capacities, travel distances, and configurations to accommodate both light-duty and heavy-duty applications. Proper selection and installation of the screw jack ensure optimal performance and safety in diverse tasks.

Which industries and sectors commonly rely on screw jacks for their operations?

Screw jacks find applications in various industries and sectors where lifting heavy loads, adjusting height, or precise positioning is required. Here are some of the industries and sectors that commonly rely on screw jacks for their operations:

- Manufacturing: Screw jacks are extensively used in manufacturing industries for tasks such as lifting and positioning heavy equipment, adjusting assembly line heights, and aligning components during production processes.

- Construction: The construction industry utilizes screw jacks for tasks like lifting and stabilizing structural elements during building construction, adjusting formwork and scaffolding heights, and positioning heavy machinery or materials.

- Automotive: In the automotive sector, screw jacks are employed for lifting vehicles during maintenance and repairs, adjusting conveyor heights in assembly lines, and positioning components during manufacturing processes.

- Transportation and Logistics: Screw jacks are used in transportation and logistics for tasks such as adjusting loading dock heights, raising or lowering platforms on trucks or trailers, and positioning cargo handling equipment.

- Entertainment and Events: The entertainment and events industry relies on screw jacks for stage setups, lifting and adjusting lighting equipment, raising or lowering platforms for performers, and creating dynamic stage effects.

- Aerospace and Defense: Screw jacks are utilized in the aerospace and defense sectors for applications such as adjusting heights of launch platforms, positioning aircraft components during assembly, and operating heavy-duty doors or hatches.

- Material Handling and Warehousing: Screw jacks are found in material handling and warehousing operations for tasks like adjusting conveyor heights, lifting heavy pallets or containers, and positioning racks or shelves.

- Mining and Heavy Machinery: The mining industry and sectors involving heavy machinery utilize screw jacks for lifting and positioning equipment, adjusting conveyor heights, and supporting heavy loads in various mining operations.

- Energy and Utilities: Screw jacks are employed in energy and utility sectors for tasks such as adjusting heights of solar panels or wind turbines, raising or lowering equipment in power plants, and positioning components in utility infrastructure.

- Medical and Rehabilitation: In the medical and rehabilitation fields, screw jacks are used for height adjustment of medical beds, positioning of imaging equipment, and providing adjustable support systems for patients.

This list is not exhaustive, and screw jacks may find applications in other industries and sectors beyond those mentioned. The versatility, load capacity, and precise control offered by screw jacks make them valuable tools in a wide range of operations requiring lifting, adjusting, or positioning heavy loads.

editor by CX 2023-11-21