Product Description

Product Description

A heavy-duty roller shaft is a special type of mechanical part that is often used in industrial equipment and mechanical transmission systems. Function: Heavy-duty hollow flange shafts are typically used to connect 2 or more rotating parts such as gears, fan blades or transmissions. It connects rotating parts fixed on the shaft through flanges so that they can rotate together and transmit force and torque. Material selection: Heavy-duty hollow flange shafts are usually manufactured with high-strength alloy steel or stainless steel to ensure that they have sufficient strength and durability. The choice of material depends on the application environment and requirements. Structural design: The heavy-duty hollow flange shaft consists of 2 main parts: the shaft body and the flange. The shaft body is hollow with a large internal diameter to reduce overall weight and provide room for other transmission components. Flanges are located at both ends of the shaft and are used to connect and fix rotating parts. Manufacturing process: The manufacturing of heavy-duty hollow flange shafts usually involves multiple operations, including turning, milling, cutting, drilling, etc. These operations are used to machine the shaft body and flange and ensure that their size and shape meet the design requirements.

|

|

|||||||||||||||||||||||||||||||||||

★★★High Load Capacity: Large helical gear shafts are designed to handle significant loads and transmit high levels of torque. The helical gear design allows for a greater tooth engagement, resulting in improved load distribution and higher load-carrying capacity compared to other gear types.

★★★Smooth and Quiet Operation: Helical gears have a gradual engagement of teeth, which reduces noise and vibration during operation. The helix angle of the teeth helps to distribute the load smoothly, minimizing impact and ensuring a quieter gear system.

★★★Increased Efficiency: The helical gear design provides a larger contact area between the teeth, resulting in higher efficiency compared to other gear types. This leads to reduced power losses and improved overall system efficiency.

★★★Greater Tooth Strength: The helical gear teeth are longer and have a larger surface area compared to spur gears, providing increased tooth strength. This makes large helical gear shafts more resistant to wear and fatigue, allowing them to withstand heavy loads and prolonged use.

★★★Improved Gear Meshing: Helical gears offer a gradual engagement of teeth, which results in a smoother meshing action. This helps to minimize backlash, improve gear accuracy, and reduce the likelihood of tooth damage during gear engagement.

★★★Versatility: Large helical gear shafts can be used in a wide range of applications, including industrial machinery, heavy equipment, marine propulsion systems, and power transmission systems. Their versatility makes them suitable for various industries and sectors.

★★★Reliability and Durability: The use of high-quality materials, precise manufacturing techniques, and rigorous quality control ensures that large helical gear shafts are reliable and durable. They are designed to withstand heavy loads, extreme operating conditions, and long service life.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

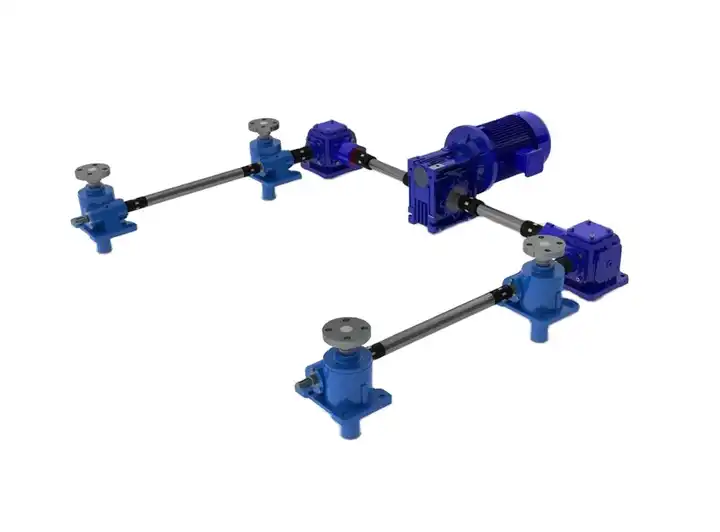

How do screw jacks ensure controlled and synchronized movement in multi-jack systems?

Screw jacks are capable of ensuring controlled and synchronized movement in multi-jack systems through various mechanisms and techniques. These systems are commonly used in applications where multiple screw jacks need to work together to lift or position a load. Here’s how screw jacks achieve controlled and synchronized movement in multi-jack systems:

- Mechanical Synchronization: Screw jacks can be mechanically linked in a multi-jack system to ensure synchronized movement. This can be achieved through the use of rigid couplings, connecting rods, or gear mechanisms that interconnect the input shafts of individual screw jacks. As a result, when one screw jack is operated to lift or lower the load, the mechanical linkage transfers the motion to the other screw jacks, causing them to move in sync. This ensures that all jacks contribute proportionally to the load and maintain a consistent lifting height.

- Electrical Synchronization: In addition to mechanical synchronization, screw jacks can also be electrically synchronized in multi-jack systems. This is typically achieved through the use of motorized screw jacks controlled by a centralized control system. Each motorized screw jack is equipped with position sensors or encoders that provide feedback on their current position. The control system receives this feedback and adjusts the motor speed and direction for each screw jack to ensure synchronized movement. Electrical synchronization enables precise control and allows for adjustments to be made dynamically, compensating for any variations in load distribution or environmental conditions.

- Load Sharing Mechanisms: In multi-jack systems, load sharing mechanisms can be employed to distribute the weight evenly among the screw jacks. Load sharing mechanisms can include load sensors or load cells that measure the individual loads on each jack. The control system then adjusts the lifting force applied by each screw jack to ensure equal distribution of the load. This prevents overloading of any individual jack and promotes balanced movement in the system.

- Position Feedback and Control: Screw jacks in multi-jack systems can be equipped with position feedback devices, such as linear encoders or limit switches, that provide information on the position of the load. This feedback is used by the control system to precisely control the movement of the screw jacks, ensuring that they reach and maintain the desired positions. By continuously monitoring the position feedback, the control system can make adjustments to keep the jacks synchronized and maintain the desired level of control.

- Control System Integration: A centralized control system can be used to integrate and coordinate the operation of multiple screw jacks in a multi-jack system. This control system can utilize programmable logic controllers (PLCs) or computer numerical control (CNC) systems to manage the movement, synchronization, and safety aspects of the screw jacks. The control system enables precise control, real-time monitoring, and the implementation of safety features, enhancing the overall performance and reliability of the multi-jack system.

By employing these mechanisms and techniques, screw jacks ensure controlled and synchronized movement in multi-jack systems. These systems find applications in various industries, such as heavy lifting, material handling, and industrial automation, where precise positioning and synchronized operation are critical requirements.

How do screw jacks ensure smooth and controlled linear movement of loads?

Screw jacks are designed to ensure smooth and controlled linear movement of loads. They employ several mechanisms and features that contribute to this capability. Here are some ways in which screw jacks achieve smooth and controlled linear movement:

- Threaded Screw and Nut Mechanism: Screw jacks consist of a threaded screw and a matching nut. The screw is rotated using a handle or a motor, causing it to move linearly through the nut. The thread geometry allows for smooth and controlled movement as the screw advances or retracts. The precision of the screw thread ensures that the load moves linearly without jerks or sudden changes in speed.

- Low Friction and High Efficiency: Screw jacks are designed to minimize friction and maximize efficiency. The components of the screw jack, such as the screw, nut, and bearing surfaces, are manufactured with smooth and precise finishes. This reduces frictional forces and minimizes energy losses during operation. The low friction characteristics enable smooth movement and ensure that a significant portion of the input force is translated into lifting or lowering the load.

- Load Distribution and Stability: Screw jacks are designed to distribute the load evenly across the screw thread and nut. This ensures that the load is supported and guided in a stable manner during linear movement. The load-bearing components of the screw jack, such as the housing and base, are constructed to provide adequate strength and rigidity, minimizing deflection and maintaining stability throughout the lifting or lowering process.

- Anti-Backlash Mechanisms: Backlash refers to the slight axial movement or play that can occur between the screw and the nut in a screw jack. To minimize backlash and ensure precise control, screw jacks often incorporate anti-backlash mechanisms. These mechanisms, such as preloading springs or adjustable backlash nuts, reduce or eliminate any free movement, allowing for more accurate and controlled linear motion of the load.

- Overload Protection: Screw jacks may include overload protection features to prevent damage or failure in the event of excessive loads or unexpected conditions. These features can include mechanical stops, shear pins, or overload clutches that disengage or limit the load-carrying capacity of the screw jack when predetermined limits are exceeded. Overload protection mechanisms contribute to the safe and controlled movement of loads.

By employing a threaded screw and nut mechanism, minimizing friction, ensuring load distribution and stability, incorporating anti-backlash mechanisms, and providing overload protection, screw jacks enable smooth and controlled linear movement of loads. These features make screw jacks suitable for a wide range of applications where precise positioning, lifting, or lowering with controlled speed and stability is required.

What is a screw jack and how is it used in various applications?

A screw jack is a mechanical device that converts rotational motion into linear motion. It consists of a threaded shaft (screw) and a nut that engages with the screw. When the screw is rotated, it moves the nut along the screw’s threads, causing linear displacement. Screw jacks are commonly used in various applications where heavy loads need to be lifted, lowered, or positioned with precision. Here are some key points regarding screw jacks and their applications:

- Principle of Operation: Screw jacks operate based on the principle of linear motion generated by the rotary motion of the screw. When the screw is rotated using a handle, motor, or other power source, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution.

- Lifting and Lowering Heavy Loads: Screw jacks are frequently used for lifting and lowering heavy loads in various industries. They provide a mechanical advantage, allowing operators to exert relatively low force to move substantial loads vertically. Screw jacks are commonly used in applications such as automotive lifts, industrial machinery, stage rigging, and construction equipment.

- Precision Positioning: Screw jacks are capable of precise positioning due to their ability to control linear displacement. By accurately controlling the rotational motion of the screw, the nut can be moved with high precision, enabling precise positioning of loads or equipment. This makes screw jacks suitable for applications that require fine adjustments, such as in assembly lines, testing equipment, or positioning systems.

- Load Capacity: Screw jacks are designed to handle a wide range of load capacities, from relatively light loads to extremely heavy loads. The load capacity of a screw jack depends on factors such as the diameter and pitch of the screw, the material and design of the components, and the mechanical arrangement of the jack. Specialized screw jacks can be engineered to handle loads ranging from a few kilograms to several hundred tons.

- Multiple Jack Systems: In applications that require lifting or moving exceptionally heavy loads or to distribute the load evenly, multiple screw jacks can be used in a synchronized arrangement. By mechanically linking several screw jacks together, they can be operated simultaneously to ensure coordinated and balanced lifting or lowering of the load.

- Automation and Motorization: While manual operation using a handle is common for smaller loads, larger and more complex applications often utilize motorized or automated systems. Electric motors, hydraulic systems, or pneumatic systems can be integrated with screw jacks to provide power and control for lifting or positioning operations. This enables efficient and precise operation, especially in industrial or automated processes.

Screw jacks are versatile mechanical devices used for lifting, lowering, and positioning heavy loads with precision. Their applications range from simple manual operations to complex automated systems, making them indispensable in various industries that require controlled linear motion and load handling.

editor by Dream 2024-04-25

China wholesaler 316 304 Stainless Steel Rod Long 2mm 8mm Aluminum Shaft Pin 25mm 40mm Threaded Knurled Shaft Price Steel Metal Shaft screw feeder shaft

Product Description

Product Description

Product Description

Product Name:316 304 stainless steel rod long 2mm 8mm aluminum shaft pin 25mm 40mm threaded knurled shaft price steel metal shaft

Company Name:

HangZhou CHINAMFG Hardware Industry Co., Ltd.

Keywords:

Shaft, Custom Precision Shaft, Precision Shaft, CNC Parts Screw, Special Screw, Stainless Steel Screws, Screw, Custom Stainless Steel Screw, Stainless Steel Screw Bolts, 316 Stainless Steel Screws, 316L Stainless Steel Screw, 304 Stainless Steel Screw, Screw Stainless Steel 316, Custom Screws Stainless, Stainless Steel Screws, Steel Screw Stainless, Screw Stainless Steel, Head Screw Stainless, 316 Steel Screws, Custom Shaft

Attributes:

- Material: Carbon Steel

- Load: Drive Shaft

- Stiffness / Rigid Axle

Description:

Explore our range of nonstandard CNC machining turning stainless steel shafts. Made from high-quality 304 and 316 stainless steel, these custom precision shafts offer exceptional strength and durability. Perfect for various applications, including drive shafts, these shafts provide stiffness and rigidity. Choose from a wide selection of sizes and designs to meet your specific needs. Trust HangZhou CHINAMFG Hardware Industry Co., Ltd. for reliable and precise CNC parts.

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, AL6082-T6 etc. |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H58,H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP,PEI, Peek etc. |

Nonstandard CNC Machining Turning Stainless Steel Shafts

Nonstandard CNC Machining Turning Stainless Steel Shafts

Looking for custom precision shafts? Our stainless steel screws are made from high-quality 304 and 316 stainless steel. With a rigid axle and excellent stiffness, these shafts are perfect for drive shaft applications. Order your custom shafts today!

Company name: HangZhou CHINAMFG Hardware Industry Co., Ltd.

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc plating | Nickel plating |

| Color Anodized | Passivating | Nickel plating | chrome plating |

| Sandblast Anodized | Sandblasting | Chrome plating | Electrophoresis black |

| Polishing | Laser engraving | Oxide black | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Chroming | Oxide black | Heat treatment | |

| Chemical Film | Powder Coated |

Company Profile

CHINAMFG Hardware – Precision CNC Spare Parts

JIESHENG Hardware – Precision CNC Spare Parts

JIESHENG Hardware, a leading manufacturer in the industry, specializes in the production of precision CNC lathes, automatic lathe parts, precision non-standard parts, rivets and nuts, washers, stamping parts, and more. Our expertise lies in providing high-quality non-standard metal parts to clients in various industries.

Our products are made from a wide range of materials including stainless steel, copper, brass, bronze, iron, aluminum, and various types of steel. This versatility allows us to cater to the specific needs of industries such as electronics, hardware, lighting, toys, sanitary ware, furniture, medical, sports equipment, and more.

Choose CHINAMFG Hardware for:

- Precision CNC lathes and automatic lathe parts

- High-quality non-standard metal parts

- Rivets, nuts, washers, and stamping parts

- Materials including stainless steel, copper, brass, bronze, iron, aluminum, and various types of steel

- Catering to industries such as electronics, hardware, lighting, toys, sanitary ware, furniture, medical, sports equipment, and more

Trust CHINAMFG Hardware, a leading manufacturer in the industry, for all your precision CNC spare part needs.

Product Details

Product Description: Brass Insert Sharp Knurl Nuts for Thermoplastics

Product Description: Brass Insert Sharp Knurl Nuts for Thermoplastics

Introducing our high-quality Brass Insert Sharp Knurl Nuts specifically designed for thermoplastics. These nuts are perfect for various applications and offer exceptional performance and durability.

Key Features:

- Precision manufacturing using top-grade materials

- Available in various sizes to meet your specific requirements

- Compatible with different materials such as aluminum, copper, brass, stainless steel, steel, iron, alloy, and zinc

- Sharp knurl design ensures a secure and reliable grip

- Surface treatment options include polishing, anodizing, nickel plating, zinc plating, tin plating, chrome plating, and silver plating

- Excellent hardness for enhanced strength and longevity

- Optimal packaging to ensure safe delivery

How to Request a Quotation:

Before requesting a quotation, please provide us with the following information:

- Size drawing (If unavailable, please provide detailed product size and picture)

- Material (Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc, etc.)

- Quantity (Higher quantities may result in better pricing)

- Surface treatment preference

- Required hardness

- Packing term

If you are interested in brass tubular rivets, please feel free to contact us.

Contact Information:

Contact Person: Alice Lee

Company: HangZhou CHINAMFG Hardware Industry Co., Ltd.

FAQ

Stainless Steel Dowel Pins

Stainless Steel Dowel Pins

Are you in need of stainless steel dowel pins for your manufacturing needs? Look no further! HangZhou CHINAMFG Hardware Industry Co., Ltd. is here to provide you with high-quality dowel pins that meet your requirements.

Features:

- Made from durable stainless steel material

- Precision machined for accurate dimensions

- Available in various sizes and lengths

- Corrosion-resistant for long-lasting performance

Benefits:

- Ensures secure and reliable connections

- Reduces the risk of misalignment

- Increases the strength and stability of assembled parts

- Can withstand high temperatures and harsh environments

Sample Request:

If you would like to request a sample of our stainless steel dowel pins, simply contact us and provide the necessary details. We may require a sample cost, but it will be refunded once you proceed with a mass production order. In special conditions, we also offer free samples.

Lead Time:

The lead time for your order depends on the quantity. Generally, it takes 7-20 days after order confirmation for us to fulfill your requirements.

Urgent Orders:

If you have urgent manufacturing needs, don’t worry! We will do our best to assist you. As we have our own factory, we can be flexible in adjusting our production schedule to accommodate your urgent requests.

Confidentiality:

We understand the importance of keeping your designs confidential. If you require a non-disclosure agreement (NDA), we are more than willing to CHINAMFG it. Rest assured that we will not display or share your designs with anyone.

Company name: HangZhou CHINAMFG Hardware Industry Co., Ltd.

Production Updates:

At HangZhou CHINAMFG Hardware Industry Co., Ltd., we understand that not everyone can visit our factory in person. But that doesn’t mean you have to miss out on the production process! We are committed to keeping you informed every step of the way.

When you choose our products, we will provide you with a detailed production schedule. This schedule will outline the key HangZhoustones and timelines, ensuring you know exactly when your order will be completed.

But we don’t stop there. We want you to see the progress for yourself. That’s why we will also send you pictures and videos showcasing the machining progress. You’ll be CZPT to witness the precision and craftsmanship that goes into every product we make.

With HangZhou CHINAMFG Hardware Industry Co., Ltd., you can have peace of mind knowing that even if you can’t be here in person, you won’t miss a beat. We keep you connected to the production process, so you can feel confident in the quality and progress of your order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can screw jacks be integrated with control systems for automation and remote operation?

Yes, screw jacks can be integrated with control systems to enable automation and remote operation. This integration allows for enhanced control, monitoring, and synchronization of multiple screw jacks within a system. Here’s how screw jacks can be integrated with control systems:

- Motorized Screw Jacks: Motorized screw jacks are equipped with electric motors that provide the power required for lifting and adjusting loads. These motorized screw jacks can be integrated with control systems to enable automation and remote operation. The control system can include a programmable logic controller (PLC), human-machine interface (HMI), or a dedicated control unit.

- Communication Protocols: Screw jacks integrated with control systems can use various communication protocols to facilitate remote operation and automation. Common protocols include Modbus, CAN bus, Ethernet/IP, or Profinet. These protocols allow the control system to communicate with the motorized screw jacks, sending commands, receiving feedback, and monitoring their status.

- Position Feedback: Motorized screw jacks integrated with control systems can provide position feedback, allowing the control system to accurately monitor and control the position of the screw jacks. Position sensors, such as encoders or linear potentiometers, can be installed on the screw jacks to provide precise position data to the control system.

- Programming and Sequencing: Control systems can be programmed to execute specific sequences of movements and actions using motorized screw jacks. This programming can include predefined motion profiles, synchronized movements of multiple screw jacks, or customized sequences to meet specific application requirements.

- Remote Operation and Monitoring: Integration with control systems allows for remote operation and monitoring of screw jacks. Through the control system’s interface, operators can remotely control the screw jacks, adjust their positions, monitor their status, and receive real-time feedback on load, position, or any potential issues.

- Integration with Overall Automation Systems: Screw jacks integrated with control systems can be part of larger automation systems, where they work in conjunction with other devices, such as sensors, actuators, or safety systems. This integration enables seamless coordination and synchronization of multiple components to achieve complex automation tasks.

The integration of screw jacks with control systems for automation and remote operation provides numerous benefits, including improved efficiency, precise control, enhanced safety, and the ability to monitor and adjust loads in real-time. This integration is particularly advantageous in applications that require synchronized movement, precise positioning, or remote control of multiple screw jacks within a system.

How do screw jacks enhance the performance of lifting and leveling applications?

Screw jacks are versatile mechanical devices that enhance the performance of lifting and leveling applications in several ways. Here are some ways in which screw jacks contribute to improved performance:

- Precise Positioning: Screw jacks offer precise positioning control, allowing for accurate adjustment of height or level. The threaded screw mechanism provides fine incremental movements, enabling operators to achieve the desired position with high precision. This level of control is crucial in applications where precise alignment, leveling, or height adjustment is required.

- Heavy Load Capacity: Screw jacks are capable of lifting and supporting heavy loads. They are designed to handle substantial weight and provide reliable load-bearing capabilities. The mechanical advantage of the screw thread allows for efficient transfer of force, enabling screw jacks to handle loads that would be impractical or challenging for other lifting mechanisms.

- Stability and Safety: Screw jacks offer stability and safety during lifting and leveling operations. The threaded screw mechanism ensures that the load remains secure and stable in the desired position, minimizing the risk of accidental movement or shifting. Screw jacks are designed with safety features such as locking mechanisms or braking systems to prevent unintended lowering or sudden movements, enhancing overall safety for both operators and the lifted load.

- Adjustability and Flexibility: Screw jacks provide adjustability and flexibility in lifting and leveling applications. They can be easily adjusted to accommodate different heights or levels, making them suitable for a wide range of applications. Screw jacks are available in various sizes, load capacities, and configurations, allowing for customization and adaptation to specific requirements.

- Reliability and Durability: Screw jacks are known for their reliability and durability. They are constructed with robust materials and designed to withstand heavy loads, frequent use, and harsh operating conditions. The screw thread mechanism is inherently resistant to wear and provides excellent load-holding capabilities, ensuring long-term performance and reliability.

- Manual or Motorized Operation: Screw jacks can be operated manually or with motorized systems, providing flexibility in choosing the appropriate mode of operation based on the specific application. Manual screw jacks are often used when precise control is required, while motorized screw jacks offer increased speed and automation for lifting or leveling larger or heavier loads.

By offering precise positioning, high load capacity, stability, adjustability, reliability, and flexibility in operation, screw jacks significantly enhance the performance of lifting and leveling applications. Their versatility and ability to handle heavy loads make them a preferred choice in various industries where controlled lifting, leveling, or positioning is essential.

Can screw jacks be adapted for both vertical and horizontal lifting applications?

Yes, screw jacks can be adapted for both vertical and horizontal lifting applications. Screw jacks are versatile mechanical devices that can be configured and mounted in various orientations to accommodate different lifting requirements. Here’s how screw jacks can be adapted for vertical and horizontal lifting applications:

- Vertical Lifting: Screw jacks are commonly used for vertical lifting applications. In vertical lifting configurations, the screw jack is mounted in a vertical position, with the load being lifted or lowered along the vertical axis. Vertical lifting applications include lifting platforms, stage equipment, heavy machinery, and other scenarios where vertical movement is required. Screw jacks designed for vertical lifting typically feature self-locking mechanisms to ensure load stability when the screw is not being rotated. The load is supported by the screw jack’s structure, which is constructed to handle the vertical forces exerted during lifting.

- Horizontal Lifting: Screw jacks can also be adapted for horizontal lifting applications. In horizontal lifting configurations, the screw jack is mounted in a horizontal position, and the load is moved horizontally or at an angle. Horizontal lifting applications can include conveyor systems, sliding gates, adjustable workstations, and other scenarios where linear movement is required along a horizontal plane. To adapt a screw jack for horizontal lifting, additional support mechanisms may be employed to counteract the gravitational forces acting on the load. These support mechanisms can include guide rails, linear guides, or additional bracing to maintain stability and control during horizontal movement.

- Angular Lifting: Screw jacks can be further adapted for angular lifting applications where the load needs to be lifted or lowered along an inclined or diagonal plane. Angular lifting configurations require careful consideration of the load’s weight distribution, the angle of inclination, and the stability of the supporting structure. By appropriately positioning and supporting the screw jack, angular lifting applications can be achieved with precision and control.

- Mounting Flexibility: Screw jacks offer flexibility in terms of mounting options, allowing them to be adapted for various orientations. The mounting flexibility enables screw jacks to be integrated into different lifting systems and structures. Depending on the specific requirements of the application, screw jacks can be mounted using flanges, brackets, or other mounting accessories. This adaptability facilitates the use of screw jacks in both vertical and horizontal lifting applications.

In summary, screw jacks can be adapted for both vertical and horizontal lifting applications. By considering factors such as load requirements, gravitational forces, stability needs, and mounting flexibility, screw jacks can be configured and mounted to provide stable and controlled lifting in various orientations.

editor by Dream 2024-04-24

China Standard Normal-Duty Insert Bearing with Long Service Life screw shaft que es

Product Description

NU 204 ECPHA

Detailed Photos

Insert bearings are based on sealed deep groove ball bearings. This variant is intended for use in applications where the direction of rotation is constant. It has a narrow inner ring extended on 1 side, with an eccentric locking collar, enabling quick and easy mounting CZPT the shaft.

- Designed for rotation in 1 direction

- Quick and easy to mount CZPT the shaft

- Long service life

- Reduce noise and vibration levels

Product Description

Dimensions

| Bore diameter | 33.338 mm |

| Outside diameter | 72 mm |

| Width, total | 38.9 mm |

| Width, inner ring | 25.4 mm |

| Width, outer ring | 19 mm |

Performance

| Basic dynamic load rating | 25.5 kN |

| Basic static load rating | 15.3 kN |

| Limiting speed | 5 300 r/min |

| Note | Limiting speed with shaft tolerance h6 |

Dimensions

| d |

33.338 mm |

Bore diameter |

|---|---|---|

| D |

72 mm |

Outside diameter |

| B1 |

38.9 mm |

Overall bearing width |

| B |

25.4 mm |

Width of inner ring |

| C |

19 mm |

Width of outer ring |

| d1 |

≈ 46.1 mm |

Outside diameter of inner ring |

| d2 |

51.1 mm |

Outside diameter of locking collar |

| B4 |

6.75 mm |

Distance from side face to thread centre |

| r1,2 |

min. 1 mm |

Chamfer dimension of inner ring |

| s1 |

29.4 mm |

Distance from locking device side face to raceway centre |

Calculation data

| Basic dynamic load rating | C |

25.5 kN |

|---|---|---|

| Basic static load rating | C0 |

15.3 kN |

| Fatigue load limit | Pu |

0.655 kN |

| Limiting speed |

5 300 r/min |

|

|

Limiting speed with shaft tolerance h6 |

||

| Calculation factor | f0 |

14 |

Company Profile

ZheJiang CZPT Industrial Technology Co., Ltd set up since 1997, with 20 years development, we become 1 of the best companies in the industry for mechanical and electrical products system integration, logistics service and investment. The company has set up 21 subsidiaries located in southern, central, eastern and northern China, .

The products categories include:

1, Transmission Products: High and low voltage electric motors, geared motors, gear boxes, bearings, inverter and complete electrical cabinets

2, Automation Products: Automation systems, motion control, low voltage control products and systems, sensor and communication products,

3, Power distribution Products: Low-voltage power distribution products, medium voltage circuit breaker, intelligent building system and equipment.

4, Machinery components.

Count on our 20 years industry experiences. ZheJiang CZPT Industrial Technology Co., Ltd give you one-stop industrial products sourcing, procurement, system integration and services, satisfy your different needs in the industry.

We are looking CHINAMFG to cooperating with you.

Office Block

Warehouse Block

FAQ

1. Who are we?

We are based in HangZhou, China, start from 2015,sell to DomesticMarket(89.00%),Eastem Europe(3.00%),SoutheastAsia(2.00%),SouthAmerica(2.00%),Northern Europe(1.00%),Western Europe(1.00%),Oceania(1.00%),NorthAmerica(1.00%) There are total about 11-50 people in our office.

2. How about the after services and technical?

We offer 24 hours online customer service and The technical support and guidance online.

3. How can we guarantee quality?

Always a pre-production sample before mass production,Always final Inspection by Take photo and video as your demands before shipment:We provide you 3 months guarantee for used and 1 YEAR warranty for new.

4. How about the packing when they are sent out?

In order to save the freight and reduce your budget, we choose the packaging forenvironment-friendly. We use foam board with 3 cm thick to fill in all around the box insideto protect parts, then use carton to pack the parts, but if thev are too heavy, we wilcustomized the wooden box for them.

5. What terms services can we provide?

1:Payment: T/T, Paypal, Western union, etc

2:Express: UPS,DHL,FEDEX,TNT,EMS ,etc

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do screw jacks impact the overall cost-effectiveness of industrial processes?

Screw jacks have a significant impact on the overall cost-effectiveness of industrial processes. They offer several advantages that contribute to cost savings, improved efficiency, and increased productivity. Here’s how screw jacks impact the cost-effectiveness of industrial processes:

- Precision and Accuracy: Screw jacks provide precise and accurate positioning, alignment, and movement of components. This precision reduces errors, rework, and scrap, resulting in higher product quality and lower production costs. Accurate positioning also improves the efficiency of assembly, reducing the time required for adjustments and alignments.

- Flexibility and Adaptability: Screw jacks are versatile and can be customized to meet specific requirements. They can be easily integrated into existing systems or machinery, allowing for cost-effective modifications or upgrades. Their adaptability enables the optimization of processes, reducing the need for expensive equipment replacements.

- Load Handling Capacity: Screw jacks have high load handling capacities, allowing them to support heavy loads. This eliminates the need for additional equipment or specialized machinery, reducing capital investment and operational costs. The ability to handle substantial loads efficiently also improves productivity and throughput.

- Maintenance and Durability: Screw jacks are designed for durability and require minimal maintenance. Their robust construction and use of materials that withstand harsh environments contribute to their long service life. Reduced maintenance requirements result in lower maintenance costs and less downtime, leading to increased overall productivity.

- Energy Efficiency: Screw jacks offer energy-efficient operation. They consume power only during movement or adjustment and require no power when holding a position. This energy efficiency reduces operational costs and contributes to a greener and more sustainable approach to industrial processes.

- Safety and Operator Ergonomics: Screw jacks can improve safety and operator ergonomics in industrial processes. They allow for controlled and precise movement, reducing the risk of accidents or injuries. Moreover, screw jacks can be designed to facilitate ergonomic positioning of workpieces, reducing strain on operators and enhancing their productivity.

- Reliability and Longevity: Screw jacks are known for their reliability and long service life. Their robust construction and use of high-quality materials ensure dependable performance even in demanding industrial environments. The reduced need for frequent replacements or repairs contributes to cost savings in the long run.

By offering precision, flexibility, efficiency, durability, and safety, screw jacks positively impact the cost-effectiveness of industrial processes. They optimize productivity, reduce operational expenses, and enhance the overall efficiency of manufacturing, assembly, and material handling processes.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by CX 2024-04-02

China supplier OEM Non-Standard 42CrMo Forged Steel Long Spline Transmission Shaft set screw bearing shaft tolerance

Product Description

Other attributes

Place of Origin

HangZhou,ZheJiang ,China

Type

Forging Parts

Spare Parts Type

Spindle

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

New Product 2571

Warranty

12 Months

Key Selling Points

Long Service Life

Weight (KG)

1200 KG

Applicable Industries

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining, Other

Local Service Location

None

Showroom Location

None

Brand Name

Yogie

Condition

New

Material

Alloy steel

Plating

anti-rust oil

Name

42CrMo Customized Large Forging Steel Rolling Mill Spare Part Roller

Quality

High Precision

Process

Lathing, milling,grinding,drilling

Heat treatment

heat treatment will be done

Diameter

860mm

Length

8000mm

Tolerance

±0.05

Torque Capacity

According to drawings

Inspection

chemical components, UT, dimension inspection

Certification

ISO

Packaging and delivery

Packaging Details

Plywood case

Port

ZheJiang ,HangZhou Port

Package Type:

Plywood case

attribute-list

Supply Ability

10000 Piece/Pieces per Year

Lead time

| Quantity (kilograms) | 1 – 1000 | > 1000 |

| Lead time (days) | 60 | To be negotiated |

Production Process

We can produce various specifications of gear, meanwhile, we can also provide gear blanks.

We have a full set of production processes and testing instruments for forging, heat treatment and machining.

We have 5 medium frequency furnaces and 5 electric slag heavy furnaces, which can produce 1 ton-18 tons of various types of alloy steel, with an annual capacity of 10,000 tons. The main characteristics of electroslag remelting are that it can flexibly produce various types of special steel in size and batch, with pure composition, uniform and dense crystal organization.

Natural gas digital display computer temperature control heating CZPT can accurately control the heating temperature of raw materials.

800T fast forging machine can quickly forge products, 3150T and 5000T oil press can forge heavy-duty axle products. They can guarantee the forging ratio required by the product, and ensure a good metallographic structure.

More than 20 digital display resistance furnaces can be used fot normalizing, quenching and tempering products, at the same time, there are induction quenching and carburization process, so as to ensure the mechanical performance requirements of the gear

We have a number of , HOFLER and other gear rolling machine, inner tooth ring milling machine, gear insertion machine, gear grinding machine and car milling CZPT center and other gear processing equipment.

TS regards Quality as the essential part of our business success. Based on your requirements, we have raw material in-coming inspection, process control and pre-shipment inspection. With advanced test equipments such as spectrometer, CMM, tensile strength tester, microscope, hardness tester, etc, TS is CZPT to apply sufficient chemical and physical inspection. According to your request, we are also capable to do X-Ray, Magnetic Testing, Ultrasonic Testing and liquid Penetrant Examination.

PRODUCT PACKAGING

OUR WORKSHOPS

COOPERATIVE BRAND

Product Packaging

Product PackaPRging

| Material: | Steel |

|---|---|

| Load: | Drive Shaft |

| Appearance Shape: | Steel |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can screw jacks be integrated with control systems for automation and remote operation?

Yes, screw jacks can be integrated with control systems to enable automation and remote operation. This integration allows for enhanced control, monitoring, and synchronization of multiple screw jacks within a system. Here’s how screw jacks can be integrated with control systems:

- Motorized Screw Jacks: Motorized screw jacks are equipped with electric motors that provide the power required for lifting and adjusting loads. These motorized screw jacks can be integrated with control systems to enable automation and remote operation. The control system can include a programmable logic controller (PLC), human-machine interface (HMI), or a dedicated control unit.

- Communication Protocols: Screw jacks integrated with control systems can use various communication protocols to facilitate remote operation and automation. Common protocols include Modbus, CAN bus, Ethernet/IP, or Profinet. These protocols allow the control system to communicate with the motorized screw jacks, sending commands, receiving feedback, and monitoring their status.

- Position Feedback: Motorized screw jacks integrated with control systems can provide position feedback, allowing the control system to accurately monitor and control the position of the screw jacks. Position sensors, such as encoders or linear potentiometers, can be installed on the screw jacks to provide precise position data to the control system.

- Programming and Sequencing: Control systems can be programmed to execute specific sequences of movements and actions using motorized screw jacks. This programming can include predefined motion profiles, synchronized movements of multiple screw jacks, or customized sequences to meet specific application requirements.

- Remote Operation and Monitoring: Integration with control systems allows for remote operation and monitoring of screw jacks. Through the control system’s interface, operators can remotely control the screw jacks, adjust their positions, monitor their status, and receive real-time feedback on load, position, or any potential issues.

- Integration with Overall Automation Systems: Screw jacks integrated with control systems can be part of larger automation systems, where they work in conjunction with other devices, such as sensors, actuators, or safety systems. This integration enables seamless coordination and synchronization of multiple components to achieve complex automation tasks.

The integration of screw jacks with control systems for automation and remote operation provides numerous benefits, including improved efficiency, precise control, enhanced safety, and the ability to monitor and adjust loads in real-time. This integration is particularly advantageous in applications that require synchronized movement, precise positioning, or remote control of multiple screw jacks within a system.

What safety precautions should be followed when operating screw jacks?

Operating screw jacks safely is essential to prevent accidents, injuries, and damage to equipment. Here are some important safety precautions that should be followed when operating screw jacks:

- Read and Understand the Manual: Before operating a screw jack, carefully read and understand the manufacturer’s instruction manual. The manual provides important safety information, operating procedures, and maintenance guidelines specific to the screw jack model. Following the manufacturer’s instructions is crucial for safe and proper operation.

- Inspect the Screw Jack: Prior to use, inspect the screw jack for any signs of damage, wear, or loose components. Check for proper lubrication and ensure that all connections and fasteners are secure. If any issues are identified, do not operate the screw jack and address the problems through maintenance or contact the manufacturer for assistance.

- Use Appropriate Personal Protective Equipment (PPE): When operating a screw jack, wear the necessary personal protective equipment (PPE) as recommended by the manufacturer and applicable safety regulations. This may include safety glasses, gloves, steel-toed shoes, or other protective gear depending on the specific application and work environment.

- Ensure Stable Support: Place the screw jack on a stable and level surface capable of supporting the load. Ensure that the supporting structure or surface is capable of withstanding the forces generated during the lifting or lowering operation. Use appropriate blocking or shoring if additional support is required.

- Do Not Exceed Load Capacity: Never exceed the load capacity specified by the manufacturer for the screw jack. Overloading the screw jack can lead to instability, component failure, or other safety hazards. It is important to know the weight of the load being lifted or supported and select a screw jack with an appropriate load rating.

- Operate Smoothly and Carefully: Operate the screw jack smoothly and carefully, avoiding sudden or jerky movements. Use the operating handle or control mechanism provided by the manufacturer and follow the recommended operating procedures. Maintain control over the lifting or lowering process, and ensure that personnel or body parts are clear of pinch points or potential hazards.

- Do Not Use as a Permanent Support: Screw jacks are not designed to be used as permanent supports or to sustain constant loads over extended periods. They are intended for intermittent or temporary use. Avoid using screw jacks as permanent supports or in situations where prolonged load-bearing is required.

- Properly Store and Maintain: After use, properly store the screw jack in a clean and dry environment. Follow the manufacturer’s maintenance guidelines for lubrication, inspection, and periodic maintenance. Regularly check the screw jack for any signs of wear, damage, or deterioration, and address any issues promptly.

- Training and Competence: Ensure that operators are adequately trained and competent in the safe operation of screw jacks. Training should cover proper use, maintenance, and understanding of the associated hazards and safety precautions.

Following these safety precautions when operating screw jacks promotes a safe working environment and helps prevent accidents or injuries. It is important to prioritize safety and adhere to the manufacturer’s guidelines and industry best practices.

How do screw jacks handle variations in load, speed, and precision?

Screw jacks are designed to handle variations in load, speed, and precision through several mechanisms and features. Here’s how screw jacks handle these variations:

- Load Variations: Screw jacks are capable of handling different load variations. The load capacity of a screw jack depends on factors such as the mechanical strength of the components, the thread design, and the material properties. By selecting the appropriate screw jack with the required load capacity and considering factors such as the load distribution, safety factors, and duty cycle, variations in load can be accommodated within the specified limits.

- Speed Variations: Screw jacks can operate at different speeds based on the application requirements. The speed of a screw jack is influenced by factors such as the pitch of the screw, the rotational speed of the input device, and the mechanical advantage of the system. By adjusting the rotational speed of the input device or selecting screw jacks with different pitch options, variations in speed can be achieved. It is important to note that higher speeds may affect the efficiency, accuracy, and load capacity of the screw jack system.

- Precision: Screw jacks offer precise positioning capabilities. The linear displacement achieved per revolution of the screw can be accurately controlled. This precision is achieved through the pitch of the screw, which determines the linear displacement per rotation. By selecting screw jacks with suitable pitch options and incorporating additional components such as limit switches or position sensors, precise positioning can be achieved with minimal backlash or play. It is important to consider the required level of precision and the specific application’s tolerance requirements when choosing the appropriate screw jack.

- Adjustability: Screw jacks provide adjustability to accommodate variations in load, speed, and precision. The system can be fine-tuned by adjusting the input device’s rotational speed, changing the pitch of the screw, or incorporating gearing mechanisms for increased mechanical advantage. This adjustability allows for optimization based on the specific operational requirements, ensuring that the screw jack system performs effectively within the desired parameters.

- Control and Feedback: Screw jacks can be equipped with control systems and feedback mechanisms to enhance load, speed, and precision management. These systems can include motor controllers, position sensors, limit switches, or even automation interfaces. By integrating such control and feedback mechanisms, the screw jack system can be monitored, adjusted, and actively controlled to handle variations in load, speed, and precision more effectively.

In summary, screw jacks handle variations in load, speed, and precision through their design features, adjustability, and the incorporation of control systems. By selecting the appropriate screw jack and considering factors such as load capacity, speed requirements, precision needs, and control mechanisms, variations in load, speed, and precision can be accommodated to meet the specific operational demands of the application.

editor by CX 2023-11-23