Product Description

Swiss CNC machine Motor Shaft for Sewing Machine parts

| Materials | Carbon steel: 10#, 18#, 1018, 22#, 1571, 40Cr, 45#, 1045, 50#, 55#, 60#, 65Mn, 70#, 72B, 80#, 82B Alloy Structure Steel: B7, 20CrMo, 42Crmo, SCM415, SCM440, 4140 High-carbon chromium bearing steel: GCr15, 52100, SUJ2 Free-cutting steel: 12L14, 12L15 Stainless steel: 1Cr13, 2Cr13, 3Cr13, 4Cr13, 1Cr17, SUS410, SUS420, SUS430, SUS416, SUS440C, 17-4, 17-4PH, 130M, 200, 201, 202, 205, 303, 303Cu, 304, 316, 316L Aluminum grade: 6061, 6063 Brass: Hpb58-2.5 (C38000), Hpb59-1 (C37710), Hpb61-1 (C37100), Hpb62-0.8 (C35000), Hpb63-0.1 (C34900), Hpb63-3 (C34500), H60, H62, H63, H65 |

| Diameter | Ø0.3-Ø25 |

| Diameter tolerance | 0.002mm |

| Roundness | 0.0005mm |

| Roughness | Ra0.05 |

| Straightness | 0.005mm |

| Hardness: | HRC/HV |

| Length | 2mm-1000mm |

| Heat treatment | 1. Oil Quenching 2. High frequency quenching 3. Carburization 4. Vacuum Heat treatment 5. Mesh belt CZPT heat treatment |

| Surface treatment | 1. Plating nickel 2. Plating zinc 3. Plating passivation 4. Plating phosphating 5. Black coating 6. Anodized treatment |

| Package | Plastic bags inside and standard cartons outside. Shipment by pallets or according to customer’s packing specifications. |

| Warranty Policy | We confirm our qualities satisfy to 99.9%, and have 6-month quality warranty |

| After Sales Service | We will follow up the requst strictly for customers and will help customers solve problems after sale. |

Swiss High-Precision CNC Machining Process

Other Category From Cold Forging Process

Company Profile

HangZhou CHINAMFG is an integrated manufacturing and trading enterprise with over 30 years of experience. We specialize in providing customized solutions for non-standard fasteners, CNC machined parts, stamping parts, and other metal products. With a sprawling facility covering an area of 5,500 square meters, we have 3 workshops including cold heading, stamping, and cnc machining.

At Hanyee Metal, we take pride in our commitment to delivering high-quality products and tailor-made solutions to meet our customers’ specific needs. Our team of skilled professionals ensures precision and CZPT in every aspect of the manufacturing process. Whether it’s fasteners for unique applications, intricately machined parts, or precision-stamped components, we have the capabilities to exceed your expectations.

Hanyee’s products exporting to more than 30 countries, especially in North American and European markets. Being the supplier for famous brands like : ITW, Ruen, Infenion, WMG,Fnox, ects. many years.

inspection

Exhibiting

Customer reception

Packaging and transportation

Customer feedback

FAQ

Q: Please send your price list for our reference.

A: We do not have standard price list because we produce according to customer design.

We can provide the quotation for your inquiries in a shortest possible time.

Q:Please quote the price for me

A: Our standard response time is 2 working hours, once you confirm the demand and drawing we shall provide the quote within 12 working hours.

Q:Can I get some sample?

A: Sure. We believe sample order is a good way to start our cooperation.

If it is a standard product, it would be for free but freight on your account.

If customized, we shall prepare the sample after receipt of development cost.

Q: Have FASTENERS 100% assembled well in stock?

A: Some of standard size is in stock. Most is OEM item out of stock.

Q: Could I use my own LOGO or design on goods?

A: Yes, Customized logo and design on mass production are available.

Q: What is the delivery time?

A: Our lead time for samples is 1 week; 15-30 days for mass production. It is usually according to the quantity and items.

Q:What payment do you accept?

A: We accept T/T, West Union,L/C,Trade Assurance in Alibaba.

Q: Can I trust you?

A: Absolutely! We are “Made In China” & “Alibaba” verified supplier.

Q: May I visit your factory?

A: You are welcome to visit us anytime. We can also pick you up from nearest airport and Train station.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Flexible Shaft |

| Journal Diameter Dimensional Accuracy: | 0.005 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Stepped Shaft |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

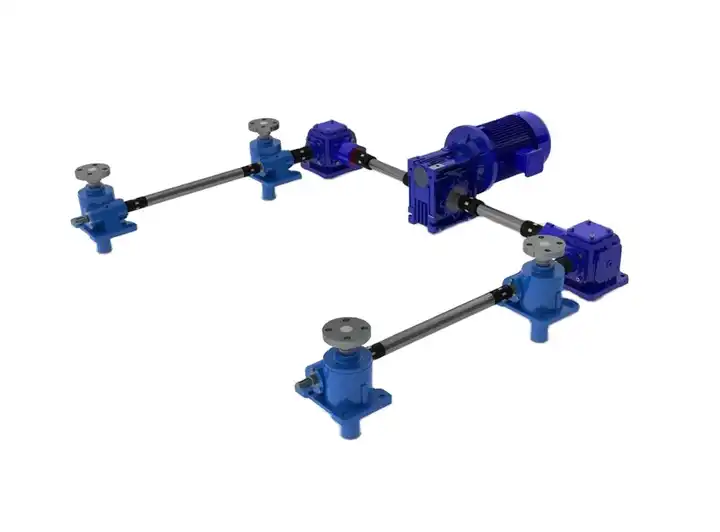

How do screw jacks handle challenges like load imbalance or uneven surfaces?

Screw jacks are designed to handle challenges such as load imbalance or uneven surfaces through various mechanisms and features. Here’s how screw jacks address these challenges:

- Load Imbalance: Screw jacks can handle load imbalance by distributing the load evenly across multiple screw jacks. In applications where there is a significant load imbalance, multiple screw jacks can be used in a synchronized system. The synchronization ensures that each screw jack shares the load proportionally, preventing excessive stress on any individual screw jack.

- Self-Locking: Screw jacks have a self-locking feature that allows them to hold their position without the need for continuous power or external braking mechanisms. This self-locking capability helps maintain stability and prevents the load from shifting even in the absence of power or during power loss.

- Anti-Backlash Mechanism: To handle challenges related to backlash or unwanted movement caused by load imbalance or vibration, some screw jacks are equipped with anti-backlash mechanisms. These mechanisms minimize or eliminate the clearance between the screw and the nut, reducing the potential for backlash and ensuring precise positioning and stability.

- Flexible Mounting Options: Screw jacks offer flexible mounting options, which allow for proper alignment and compensation on uneven surfaces. Mounting brackets or couplings can be used to adapt the screw jacks to different orientations or to compensate for variations in the mounting surface. This flexibility ensures that the screw jacks can be securely installed and adjusted to accommodate uneven surfaces.

- Guidance Systems: In some cases, screw jacks may incorporate guidance systems to improve stability and alignment. These guidance systems can include linear guides or rails that guide the movement of the screw, ensuring smooth and accurate operation even when dealing with load imbalance or uneven surfaces.

By employing these mechanisms and features, screw jacks can effectively handle challenges related to load imbalance or uneven surfaces. They provide stability, precise positioning, and the ability to distribute loads evenly, making them suitable for a wide range of applications even in demanding environments.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by Dream 2024-05-13

China Custom Custom CNC Machining Metric Machine Screws Precision Shoulder Knurled External Thread Dowel Pin screw shaft extruder

Product Description

Key attributes of Customized CNC Turning Threaded Spline Gearbox Gear Driven Motor Output Input Shaft

Industry-specific attributes of Customized CNC Turning Threaded Spline Gearbox Gear Driven Motor Output Input Shaft

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

Other attributes of Customized CNC Turning Threaded Spline Gearbox Gear Driven Motor Output Input Shaft

| Place of Origin | ZheJiang , China |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| Model Number | OEM |

| Brand Name | OEM |

| Material | Metal |

| Process | Cnc Machining+deburrs |

| Surface treatment | Customer’s Request |

| Equipment | CNC Machining Centres / Core moving machine / precision lathe / Automatic loading and unloading equipment |

| Processing Type | Milling / Turning / Stamping |

| OEM/ODM | OEM & ODM CNC Milling Turning Machining Service |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Our Service | OEM ODM Customers’drawing |

| Materials Avaliable | Stainless Steel / Aluminum / Metals / Copper / Plastic |

Best Seller of 304 Stainless Steel Polishing Finishing CNC Machining Bracket for Laser Cutting

About YiSheng

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center, CNC Lathe, precision lathe |

| Automatic loading and unloading equipment | |

| Core moving machine | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.001mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Test Equipment | Complete test lab with Projector, High-low temperature test chamber, Tensile tester Gauge, Salt fog test |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC center work range: 510mm*850mm*500mm | |

| Core moving machine work range: φ32mm*85mm | |

| Gerenal Tolerance: (+/-mm) |

CNC Machining: 0.005 |

| Core moving: 0.005 | |

| Turning: 0.005 | |

| Grinding(Flatness/in2): 0.003 | |

| ID/OD Grinding: 0.002 | |

| Wire-Cutting: 0.002 |

RFQ of Customized CNC Turning Threaded Spline Gearbox Gear Driven Motor Output Input Shaft /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do screw jacks handle challenges like load imbalance or uneven surfaces?

Screw jacks are designed to handle challenges such as load imbalance or uneven surfaces through various mechanisms and features. Here’s how screw jacks address these challenges:

- Load Imbalance: Screw jacks can handle load imbalance by distributing the load evenly across multiple screw jacks. In applications where there is a significant load imbalance, multiple screw jacks can be used in a synchronized system. The synchronization ensures that each screw jack shares the load proportionally, preventing excessive stress on any individual screw jack.

- Self-Locking: Screw jacks have a self-locking feature that allows them to hold their position without the need for continuous power or external braking mechanisms. This self-locking capability helps maintain stability and prevents the load from shifting even in the absence of power or during power loss.

- Anti-Backlash Mechanism: To handle challenges related to backlash or unwanted movement caused by load imbalance or vibration, some screw jacks are equipped with anti-backlash mechanisms. These mechanisms minimize or eliminate the clearance between the screw and the nut, reducing the potential for backlash and ensuring precise positioning and stability.

- Flexible Mounting Options: Screw jacks offer flexible mounting options, which allow for proper alignment and compensation on uneven surfaces. Mounting brackets or couplings can be used to adapt the screw jacks to different orientations or to compensate for variations in the mounting surface. This flexibility ensures that the screw jacks can be securely installed and adjusted to accommodate uneven surfaces.

- Guidance Systems: In some cases, screw jacks may incorporate guidance systems to improve stability and alignment. These guidance systems can include linear guides or rails that guide the movement of the screw, ensuring smooth and accurate operation even when dealing with load imbalance or uneven surfaces.

By employing these mechanisms and features, screw jacks can effectively handle challenges related to load imbalance or uneven surfaces. They provide stability, precise positioning, and the ability to distribute loads evenly, making them suitable for a wide range of applications even in demanding environments.

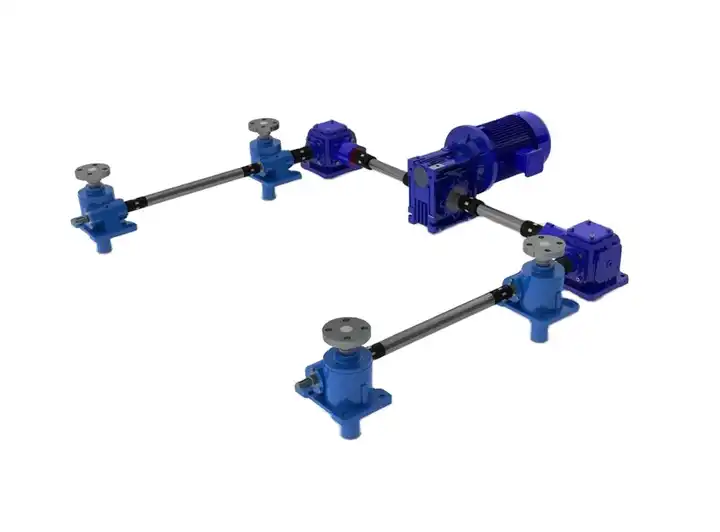

Are there any emerging trends in screw jack technology, such as automation features?

Yes, screw jack technology has been evolving, and there are several emerging trends, including the incorporation of automation features. Here are some notable trends in screw jack technology:

- Motorized Screw Jacks: Motorized screw jacks are becoming increasingly popular. These screw jacks feature integrated electric or hydraulic motors that automate the lifting and leveling process. Motorized screw jacks offer advantages such as increased speed, precise control, and the ability to handle larger loads. They are particularly useful in applications where manual operation may be impractical or when automation is desired for improved efficiency.

- Integrated Control Systems: Screw jacks are now being equipped with integrated control systems that enhance automation. These control systems can include programmable logic controllers (PLCs), human-machine interfaces (HMIs), or other electronic control units. The integration of control systems allows for centralized control, remote operation, and the ability to program complex lifting sequences or preset positions. This automation feature improves efficiency, reduces operator workload, and enhances safety.

- Position Feedback and Monitoring: Another emerging trend in screw jack technology is the incorporation of position feedback and monitoring systems. These systems utilize sensors to provide real-time feedback on the position and movement of the screw jack. By monitoring the position, operators can ensure accurate and precise positioning. Position feedback systems also enable automated control, closed-loop operation, and the ability to detect and respond to any deviations or abnormal conditions during lifting or leveling operations.

- Wireless Connectivity and Industrial IoT: Screw jacks are being integrated into wireless connectivity networks and industrial Internet of Things (IoT) systems. This allows for remote monitoring, data acquisition, and control of screw jacks. Wireless connectivity enables real-time data transmission, remote diagnostics, and predictive maintenance capabilities. By leveraging IoT technologies, screw jacks can be integrated into larger automation systems, enhancing overall operational efficiency and providing valuable insights for maintenance and optimization.

- Improved Materials and Design: Advancements in materials and design are also influencing screw jack technology. Manufacturers are utilizing high-strength materials, such as hardened steel alloys and corrosion-resistant coatings, to enhance the durability, load capacity, and lifespan of screw jacks. Additionally, innovative designs are being implemented to reduce friction, improve efficiency, and minimize wear and tear, resulting in more reliable and efficient screw jack systems.

These emerging trends in screw jack technology, including the incorporation of automation features, are aimed at improving performance, efficiency, and safety in lifting and leveling applications. As technology continues to evolve, we can expect further advancements in screw jack automation and integration with modern industrial systems.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by Dream 2024-04-29

China Standard CNC Milling Machine Processing Stainless Steel C45 Shaft From Professional Factory ball screw shaft coupling

Product Description

Introducing our high-quality Shaft, designed for various applications in the field of motors and gears. This versatile product is an essential component for any home appliance, ensuring smooth and efficient operation.

Our Shaft is expertly crafted using premium materials, guaranteeing durability and long-lasting performance. With its precise dimensions and excellent load-bearing capacity, it seamlessly integrates with motors and gears, providing optimal power transmission.

Featuring a sleek design, this Shaft is not only functional but also aesthetically pleasing. Its compact size allows for easy installation and compatibility with a wide range of home appliances

With our discounted price, you can now enhance the performance of your home appliances without breaking the bank. Don’t miss out on this incredible offer!

Keywords: Shaft, Axis, Motor Shaft, Gear

| Available Material | 1. Stainless Steel: AISI303, AISI304, AISI316, AISI416, AISI420,etc. |

| 2. Free Cutting Steel:12L14,1215,etc. | |

| 3. Steel:C45(K1045), C20,etc | |

| 4. Aluminum: Al6061, Al6063, etc. | |

| 5. Carbon Steel:AISI1006,AISI1571,AISI1571,etc. | |

| 6. Alloy Steel: SCM435,10B21,etc. | |

| 7. According to customer’s requirement | |

| Finish | Electroplating: Zinc Plating, Ni Plating, Electroless Nickel Plating, Zn-Ni Alloy Plating, Tin Plating, Copper-plating, Hot-dip Galvanizing, Black Oxide Coating, Black Anodizing, etc |

| Rust Preventive Oil | |

| Testing Equipment | CMM, Projector, Pull Tester, Projecting Apparatus |

| Salt Spray Test, Durometer, Coating Analyzer, Tensile Machine | |

| Management System | ISO9001 / IATF16949 |

| Certification | SGS, RoHS, Material Certification, PPAP |

| Production Capability | Auto Lathe Turning: ODΦ1.0-20mm, Tolerance. ± 0.01mm |

| CNC Lathe Turning: ODΦ1.0-460mm, Tolerance. ± 0.005mm | |

| CNC Milling:800x600mm (LxW), Tolerance.±0.05mm | |

| Grinding: Tolerance. ± 0.002mm | |

| Screw Cold Heading and Rolling: Metric 0.8-M16 | |

| Injection: 300T Max | |

| Stamping:2 50T Max |

1.

Location

Kexionda Electric Machinery Manufacturing Co., Ltd. (KXD) was established in 1998 and is located in the hinterland of the Pearl River CHINAMFG in South China. It is a professional enterprise that develops and produces micromotors. It now has a factory area of more than 10,000 square meters, more than 200 employees, and an annual output of 5 million motors. It mainly produces single-phase series motors (universal motors) and permanent magnet-brushed DC motors. The products are suitable for household appliances, commercial appliances, and electric equipment, such as mixers, egg beaters, meat grinders, meat mincers, ice crushers, paper shredders, bean grinders, soy milk machines, cooking machines, cloth machines, laboratory homogenizer and a series of electric products.

2.

“integrity and pragmatism”

Since its establishment, KXD has continued to innovate and win the market with integrity. The company comprehensively implements modern management, conducts production and sales based on the principle of benefiting customers, produces key parts of products by itself, continuously introduces automated production equipment, takes “quality and service” as its life, “integrity and pragmatism” as its foundation, and through its Design, production, and management are integrated to meet customer delivery deadlines to the greatest extent, effectively control product quality and reduce costs.

3.

Production standards

KXD strictly implements national standards during the production process, establishes and maintains the effective operation of the quality management system, and all products have 100% passed domestic CCC certification. All export products comply with Rohs and can pass EMC, UL, CE, VDE, and other certification requirements.

4.

Customer – first

At present, our company has dedicated project personnel to track product development, production, and after-sales service throughout the entire process, and is committed to providing customers with high-quality product solutions.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 5.33/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do screw jacks compare to other methods of lifting and adjusting loads?

When comparing screw jacks to other methods of lifting and adjusting loads, several factors come into consideration. Here’s a comparison of screw jacks with other commonly used methods:

- Hydraulic Systems: Screw jacks offer several advantages over hydraulic systems:

- Control and Precision: Screw jacks provide precise control and incremental adjustments. Hydraulic systems, on the other hand, may have limitations in terms of fine-tuning and precise positioning.

- Self-Locking: Screw jacks have a self-locking feature, which means they can hold positions without the need for continuous hydraulic pressure. Hydraulic systems typically require constant pressure to maintain position, which can be a disadvantage in certain applications.

- Simplicity and Maintenance: Screw jacks are generally simpler in design and require less maintenance compared to hydraulic systems. Hydraulic systems involve additional components such as pumps, hoses, valves, and hydraulic fluid, which can introduce complexity and maintenance requirements.

- Load Capacity: Screw jacks are available in a wide range of load capacities, making them suitable for both light-duty and heavy-duty applications. Hydraulic systems can handle higher loads but may be less suitable for precise adjustments in lighter load ranges.

- Pneumatic Systems: Screw jacks offer several advantages over pneumatic systems:

- Precision and Control: Screw jacks provide precise and controlled adjustments, allowing for accurate positioning. Pneumatic systems may have limitations in terms of fine-tuning and precise control.

- Self-Locking: Screw jacks have a self-locking feature, which allows them to hold positions without the need for continuous pneumatic pressure. Pneumatic systems require continuous pressure to maintain position, which can be a drawback in certain applications.

- Energy Efficiency: Screw jacks are typically more energy-efficient compared to pneumatic systems since they do not require a constant supply of compressed air.

- Load Capacity: Screw jacks can handle a wide range of load capacities, making them suitable for various applications. Pneumatic systems may have limitations in terms of handling heavy loads.

- Electric Actuators: Screw jacks offer several advantages over electric actuators:

- Load Capacity: Screw jacks are capable of handling high loads and are suitable for heavy-duty applications. Electric actuators may have limitations in terms of load capacity.

- Self-Locking: Screw jacks have a self-locking feature, which allows them to hold positions without the need for continuous electric power. Electric actuators may require continuous power to maintain position.

- Precision and Control: Screw jacks provide precise control and incremental adjustments. Electric actuators can offer precise positioning but may have limitations in terms of fine-tuning and incremental adjustments.

- Cost-Effectiveness: Screw jacks are often more cost-effective compared to electric actuators, making them a preferred choice in certain applications.

It’s important to note that the choice between screw jacks and other methods depends on the specific requirements of the application, such as load capacity, precision, control, maintenance, and cost considerations. Each method has its strengths and limitations, and manufacturers and engineers evaluate these factors to determine the most suitable solution for a particular lifting or adjusting task.

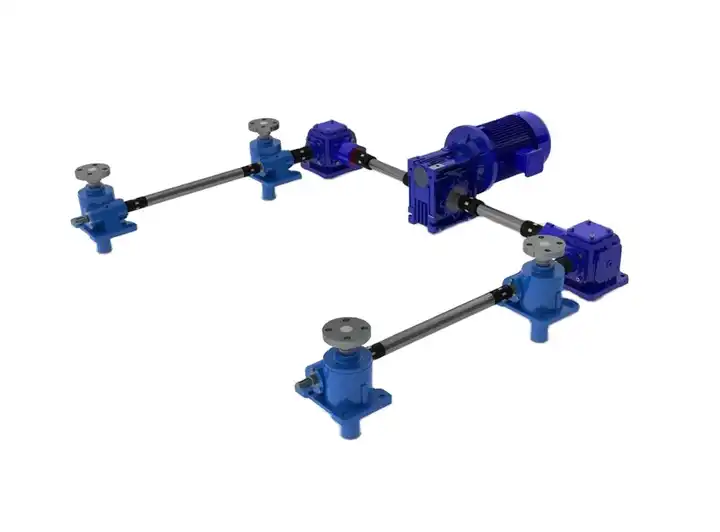

How do screw jacks enhance the efficiency of tasks like machinery assembly?

Screw jacks play a significant role in enhancing the efficiency of tasks like machinery assembly. They offer several advantages that contribute to smoother and more efficient assembly processes. Here are some ways in which screw jacks enhance efficiency:

- Precise Positioning: Screw jacks provide precise and controlled positioning, allowing for accurate alignment and assembly of machine components. The threaded screw mechanism enables incremental adjustments, enabling precise positioning and alignment during the assembly process. This precision helps ensure that components fit together correctly, reducing the need for rework or adjustments after assembly.

- Flexible Lifting and Lowering: Screw jacks allow for controlled lifting and lowering of heavy machine components during assembly. By adjusting the screw jack’s height, operators can position the components at the desired elevation, making it easier to align and attach them. The ability to fine-tune the lifting and lowering process enhances efficiency by reducing manual effort and simplifying the assembly tasks.

- Load Distribution: Screw jacks distribute the load evenly across multiple jacks or support points, providing stability during machinery assembly. This load distribution helps prevent excessive stress on individual components and ensures that the weight is properly supported. By maintaining stability and load distribution, screw jacks contribute to efficient and safe assembly processes.

- Height Adjustment: Screw jacks allow for height adjustment of machinery during assembly, enabling operators to align components at the optimal working height. This adjustability is particularly beneficial when assembling large or complex machinery, as it provides ergonomic advantages for the operators. Working at the correct height reduces fatigue and improves productivity, ultimately enhancing the efficiency of the assembly process.

- Modularity and Versatility: Screw jacks are often designed with modularity in mind, allowing them to be easily integrated into various assembly setups. They can be combined with other components such as mounting plates, couplings, or motorized systems to create customized assembly solutions. This modularity and versatility enable efficient adaptation to different assembly requirements and facilitate the integration of screw jacks into existing assembly processes.

- Automation Integration: Screw jacks can be integrated into automated assembly systems, improving efficiency by reducing manual labor and increasing the speed of assembly processes. With appropriate motorization and control systems, screw jacks can be synchronized and operated in conjunction with other automated machinery, streamlining the assembly workflow and reducing cycle times.

By providing precise positioning, flexible lifting and lowering, load distribution, height adjustment, modularity, versatility, and automation integration, screw jacks significantly enhance the efficiency of tasks like machinery assembly. They contribute to smoother operations, improved productivity, and better overall assembly quality.

Which industries and sectors commonly rely on screw jacks for their operations?

Screw jacks find applications in various industries and sectors where lifting heavy loads, adjusting height, or precise positioning is required. Here are some of the industries and sectors that commonly rely on screw jacks for their operations:

- Manufacturing: Screw jacks are extensively used in manufacturing industries for tasks such as lifting and positioning heavy equipment, adjusting assembly line heights, and aligning components during production processes.

- Construction: The construction industry utilizes screw jacks for tasks like lifting and stabilizing structural elements during building construction, adjusting formwork and scaffolding heights, and positioning heavy machinery or materials.

- Automotive: In the automotive sector, screw jacks are employed for lifting vehicles during maintenance and repairs, adjusting conveyor heights in assembly lines, and positioning components during manufacturing processes.

- Transportation and Logistics: Screw jacks are used in transportation and logistics for tasks such as adjusting loading dock heights, raising or lowering platforms on trucks or trailers, and positioning cargo handling equipment.

- Entertainment and Events: The entertainment and events industry relies on screw jacks for stage setups, lifting and adjusting lighting equipment, raising or lowering platforms for performers, and creating dynamic stage effects.

- Aerospace and Defense: Screw jacks are utilized in the aerospace and defense sectors for applications such as adjusting heights of launch platforms, positioning aircraft components during assembly, and operating heavy-duty doors or hatches.

- Material Handling and Warehousing: Screw jacks are found in material handling and warehousing operations for tasks like adjusting conveyor heights, lifting heavy pallets or containers, and positioning racks or shelves.

- Mining and Heavy Machinery: The mining industry and sectors involving heavy machinery utilize screw jacks for lifting and positioning equipment, adjusting conveyor heights, and supporting heavy loads in various mining operations.

- Energy and Utilities: Screw jacks are employed in energy and utility sectors for tasks such as adjusting heights of solar panels or wind turbines, raising or lowering equipment in power plants, and positioning components in utility infrastructure.

- Medical and Rehabilitation: In the medical and rehabilitation fields, screw jacks are used for height adjustment of medical beds, positioning of imaging equipment, and providing adjustable support systems for patients.

This list is not exhaustive, and screw jacks may find applications in other industries and sectors beyond those mentioned. The versatility, load capacity, and precise control offered by screw jacks make them valuable tools in a wide range of operations requiring lifting, adjusting, or positioning heavy loads.

editor by Dream 2024-04-25

China wholesaler CNC Machining Turning Spline Bolt Nut Round Drive Shaft for Motor Machine #8 screw shaft diameter

Product Description

Introducing our high-quality Shaft, designed for various applications in the field of motors and gears. This versatile product is an essential component for any home appliance, ensuring smooth and efficient operation.

Our Shaft is expertly crafted using premium materials, guaranteeing durability and long-lasting performance. With its precise dimensions and excellent load-bearing capacity, it seamlessly integrates with motors and gears, providing optimal power transmission.

Featuring a sleek design, this Shaft is not only functional but also aesthetically pleasing. Its compact size allows for easy installation and compatibility with a wide range of home appliances

With our discounted price, you can now enhance the performance of your home appliances without breaking the bank. Don’t miss out on this incredible offer!

Keywords: Shaft, Axis, Motor Shaft, Gear

| Available Material | 1. Stainless Steel: AISI303, AISI304, AISI316, AISI416, AISI420,etc. |

| 2. Free Cutting Steel:12L14,1215,etc. | |

| 3. Steel:C45(K1045), C20,etc | |

| 4. Aluminum: Al6061, Al6063, etc. | |

| 5. Carbon Steel:AISI1006,AISI1571,AISI1571,etc. | |

| 6. Alloy Steel: SCM435,10B21,etc. | |

| 7. According to customer’s requirement | |

| Finish | Electroplating: Zinc Plating, Ni Plating, Electroless Nickel Plating, Zn-Ni Alloy Plating, Tin Plating, Copper-plating, Hot-dip Galvanizing, Black Oxide Coating, Black Anodizing, etc |

| Rust Preventive Oil | |

| Testing Equipment | CMM, Projector, Pull Tester, Projecting Apparatus |

| Salt Spray Test, Durometer, Coating Analyzer, Tensile Machine | |

| Management System | ISO9001 / IATF16949 |

| Certification | SGS, RoHS, Material Certification, PPAP |

| Production Capability | Auto Lathe Turning: ODΦ1.0-20mm, Tolerance. ± 0.01mm |

| CNC Lathe Turning: ODΦ1.0-460mm, Tolerance. ± 0.005mm | |

| CNC Milling:800x600mm (LxW), Tolerance.±0.05mm | |

| Grinding: Tolerance. ± 0.002mm | |

| Screw Cold Heading and Rolling: Metric 0.8-M16 | |

| Injection: 300T Max | |

| Stamping:2 50T Max |

1.

Location

Kexionda Electric Machinery Manufacturing Co., Ltd. (KXD) was established in 1998 and is located in the hinterland of the Pearl River CHINAMFG in South China. It is a professional enterprise that develops and produces micromotors. It now has a factory area of more than 10,000 square meters, more than 200 employees, and an annual output of 5 million motors. It mainly produces single-phase series motors (universal motors) and permanent magnet-brushed DC motors. The products are suitable for household appliances, commercial appliances, and electric equipment, such as mixers, egg beaters, meat grinders, meat mincers, ice crushers, paper shredders, bean grinders, soy milk machines, cooking machines, cloth machines, laboratory homogenizer and a series of electric products.

2.

“integrity and pragmatism”

Since its establishment, KXD has continued to innovate and win the market with integrity. The company comprehensively implements modern management, conducts production and sales based on the principle of benefiting customers, produces key parts of products by itself, continuously introduces automated production equipment, takes “quality and service” as its life, “integrity and pragmatism” as its foundation, and through its Design, production, and management are integrated to meet customer delivery deadlines to the greatest extent, effectively control product quality and reduce costs.

3.

Production standards

KXD strictly implements national standards during the production process, establishes and maintains the effective operation of the quality management system, and all products have 100% passed domestic CCC certification. All export products comply with Rohs and can pass EMC, UL, CE, VDE, and other certification requirements.

4.

Customer – first

At present, our company has dedicated project personnel to track product development, production, and after-sales service throughout the entire process, and is committed to providing customers with high-quality product solutions.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 5.33/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can screw jacks be integrated with control systems for automation and remote operation?

Yes, screw jacks can be integrated with control systems to enable automation and remote operation. This integration allows for enhanced control, monitoring, and synchronization of multiple screw jacks within a system. Here’s how screw jacks can be integrated with control systems:

- Motorized Screw Jacks: Motorized screw jacks are equipped with electric motors that provide the power required for lifting and adjusting loads. These motorized screw jacks can be integrated with control systems to enable automation and remote operation. The control system can include a programmable logic controller (PLC), human-machine interface (HMI), or a dedicated control unit.

- Communication Protocols: Screw jacks integrated with control systems can use various communication protocols to facilitate remote operation and automation. Common protocols include Modbus, CAN bus, Ethernet/IP, or Profinet. These protocols allow the control system to communicate with the motorized screw jacks, sending commands, receiving feedback, and monitoring their status.

- Position Feedback: Motorized screw jacks integrated with control systems can provide position feedback, allowing the control system to accurately monitor and control the position of the screw jacks. Position sensors, such as encoders or linear potentiometers, can be installed on the screw jacks to provide precise position data to the control system.

- Programming and Sequencing: Control systems can be programmed to execute specific sequences of movements and actions using motorized screw jacks. This programming can include predefined motion profiles, synchronized movements of multiple screw jacks, or customized sequences to meet specific application requirements.

- Remote Operation and Monitoring: Integration with control systems allows for remote operation and monitoring of screw jacks. Through the control system’s interface, operators can remotely control the screw jacks, adjust their positions, monitor their status, and receive real-time feedback on load, position, or any potential issues.

- Integration with Overall Automation Systems: Screw jacks integrated with control systems can be part of larger automation systems, where they work in conjunction with other devices, such as sensors, actuators, or safety systems. This integration enables seamless coordination and synchronization of multiple components to achieve complex automation tasks.

The integration of screw jacks with control systems for automation and remote operation provides numerous benefits, including improved efficiency, precise control, enhanced safety, and the ability to monitor and adjust loads in real-time. This integration is particularly advantageous in applications that require synchronized movement, precise positioning, or remote control of multiple screw jacks within a system.

How do manufacturers ensure the durability and longevity of screw jacks?

Manufacturers employ various strategies and design considerations to ensure the durability and longevity of screw jacks. These measures aim to enhance the structural integrity, reliability, and resistance to wear and tear. Here are some key approaches manufacturers use to ensure the durability and longevity of screw jacks:

- High-Quality Materials: Manufacturers use high-quality materials in the construction of screw jacks to enhance their durability. Components such as screws, nuts, housing, bearings, and load-bearing parts are often made from materials such as hardened steel alloys or other durable metals. These materials offer excellent strength, resistance to deformation, and robustness, ensuring that the screw jacks can withstand heavy loads and prolonged use.

- Surface Treatments: Surface treatments and coatings are applied to screw jack components to improve their resistance to corrosion, abrasion, and wear. Common surface treatments include electroplating, powder coating, or applying specialized protective coatings. These treatments provide a layer of defense against environmental factors, such as moisture, chemicals, or abrasive particles, which can degrade the components and compromise the longevity of the screw jacks.

- Precision Manufacturing: Precision manufacturing processes are employed to ensure the accurate fabrication of screw jacks. Tight tolerances and meticulous machining techniques are utilized to achieve proper fit and alignment of components. This precision manufacturing minimizes mechanical play, reduces friction, and optimizes the overall performance of the screw jacks, contributing to their durability and longevity.

- Load Capacity and Safety Margins: Manufacturers carefully determine the load capacity of screw jacks and incorporate safety margins to ensure their long-term durability. By specifying load capacities that exceed the expected maximum loads, manufacturers provide a safety buffer that prevents the screw jacks from operating near their limits. This approach minimizes stress on the components and extends their lifespan, reducing the risk of premature failure or damage.

- Regular Maintenance Guidelines: Manufacturers provide maintenance guidelines and recommendations for screw jacks. These guidelines outline routine maintenance tasks, such as lubrication, inspection, and cleaning, that should be performed to ensure optimal performance and longevity. Following these maintenance guidelines helps prevent the accumulation of debris, corrosion, or other factors that could negatively impact the durability of the screw jacks.

- Quality Assurance Testing: Manufacturers conduct rigorous quality assurance testing to validate the durability and longevity of screw jacks. These tests may include performance testing, load testing, endurance testing, and environmental testing. By subjecting the screw jacks to stringent testing conditions, manufacturers can verify their performance, identify potential weaknesses, and make design improvements to enhance durability and longevity.

By using high-quality materials, applying surface treatments, employing precision manufacturing, incorporating load capacity and safety margins, providing maintenance guidelines, and conducting quality assurance testing, manufacturers ensure the durability and longevity of screw jacks. These measures help to deliver reliable and long-lasting products that can withstand demanding applications and operating conditions.

What factors should be considered when selecting the right screw jack for an application?

When selecting the right screw jack for an application, several factors should be taken into consideration. These factors help ensure that the chosen screw jack meets the specific requirements of the application. Here are the key factors to consider:

- Load Capacity: Determine the maximum load that the screw jack needs to lift or support. Consider both the static load (the weight of the load when stationary) and the dynamic load (additional forces or vibrations that may be present during operation). Select a screw jack with a load capacity that exceeds the application’s requirements to ensure safe and reliable operation.

- Travel Distance: Determine the required travel distance or height adjustment range of the screw jack. Consider both the minimum and maximum travel distances needed for the application. Ensure that the selected screw jack can provide the required travel distance without exceeding its mechanical limits.

- Speed Requirements: Consider the desired operating speed of the screw jack. Determine whether the application requires slow and precise movement or faster operation. The speed of the screw jack is influenced by factors such as the pitch of the screw and the rotational speed of the input device. Select a screw jack that can operate within the desired speed range without compromising other performance factors.

- Precision Needs: Assess the required level of precision for the application. Determine the allowable tolerance and backlash requirements. The precision of a screw jack is influenced by factors such as the pitch of the screw, the quality of the thread, and the presence of additional components such as limit switches or position sensors. Choose a screw jack that can achieve the desired precision level while maintaining stability and load capacity.

- Environmental Conditions: Consider the environmental conditions in which the screw jack will operate. Factors such as temperature, humidity, dust, and corrosive substances can affect the performance and durability of the screw jack. Select a screw jack that is designed to withstand the specific environmental conditions of the application.

- Mounting and Integration: Evaluate the available space for mounting the screw jack and consider the required integration with other components or systems. Determine whether the screw jack needs to be vertically mounted, horizontally mounted, or at an angle. Consider any specific mounting or interface requirements and ensure that the selected screw jack can be easily integrated into the existing system or structure.

- Safety and Compliance: Ensure that the chosen screw jack complies with safety standards and regulations applicable to the specific industry or application. Consider safety features such as self-locking mechanisms, overload protection, and emergency stop options. Verify that the manufacturer or supplier provides adequate documentation and certifications.

- Cost and Budget: Consider the budget and cost-effectiveness of the screw jack. Compare the prices and features of different screw jack models and brands. Evaluate the long-term maintenance and operational costs, including factors such as lubrication requirements and expected lifespan.

By carefully considering these factors, it is possible to select the right screw jack that meets the load capacity, travel distance, speed, precision, environmental, mounting, safety, and budget requirements of the specific application.

editor by Dream 2024-04-24

China OEM Hard CNC Machine Shaft Diameter 16mm 20mm 25mm 30mm 35mm 40mm 45mm 50mm 60mm 80mm with Chrome Plated self reversing screw shaft

Product Description

Product Description

Linear shaft is chrome plated and induction hardened, precision ground, and polished to the tolerances required by the demanding linear motion industry.It is suitable for use with linear support blocks and closed type slide units in linear motion applications. The high-carbon steel shaft is chrome plated for corrosion resistance, case hardened for wear resistance, and precision ground for consistent ball bushing radial clearance. The shaft diameter and length are specified for accurate fit and this shaft is suitable for use in applications, such as measuring systems, printing equipment, and computer numerical control (CNC) tools.

Features

1.Good finish and straightness: The surface is treated by special grinded, and then mirror polished. The surface is smooth, without cracks.

2.Corrosion resistance: Surface chrome plated(10um-20um)

3. Durable resistance: Adapting C45 high quality steel, high frequency hardness degree HRC60 ~ 64

4.High Accuracy : G6;Diameter tolerance:-0.005mm-.0.27mm; Length tolerance:+/-0.5mm(1M-3M);+/-1mm(3M-6M)

5. High Fitness: Chamfer on both ends, easier to install linear bearings and won’t hurt fingers when installing it.

| Model Number | WCS CHINAMFG Series CHINAMFG shaft(Linear rod;Steel bar;Optical axis) |

| Diameter of Linear Shaft |

Metric Diameter : 3mm,4mm,5mm,6mm,8mm,10mm,12mm,16mm, 20mm, 25mm, 30mm, 35mm,40mm, 50mm,60mm,80mm,100mm Inch Diameter : 6.35mm,9.525mm,12.7mm,15.875,19.05,25.4mm,31.75mm,38.1mm |

|

Quality |

ISO9001:2008 standard |

| Material | Steel 45#;GCR15;SUS440C |

| Hardness | HRC:58-62 |

| Hardened Layer Thickness | 0.8-3.00mm |

| Precision | G6 |

| Roughness | Within1.5μm |

|

Roughness(Rmax) |

Within 3.0μm(Rmax) |

| Straightness | Not excess 1.5μm of 100mm (Rmax) |

| Thickness of Chrome Plated | 10-20μm,15μm on average |

| Performance | Long life and low noise |

| Appearance | Smooth,Anti-corrosion,Hardened,Chrome plated |

| Service | Specisl requirement onmachining,such as threading,coaxial holes drilled and tapped,radial holes drilled and tapped,reduced shaft diameter etc;We could supply OEM to our customers. |

| Application | 3d printer machine,Machine centers,Machine tools,Precision machining machines,Heavy cutting machines,Punching machines,Marble cutting machines,Automatic equipments,Grinding machines,High speed transfer equipments,Injection molding machines,Measuring equipments |

Product Parameters

Detailed Photos

JLD Special Machining for Linear Shaft:

1. For the Length

We can offer linear shaft with diameterφ3mm-φ100mm. Maxium length up to 6000mm.

When you are special requirements on length, we can meet your machining requirements with different length.

When you request above 6000mm, we can anti-connect for you.

2. For Special Processing

When you have special requirements on machining. Such as threading, coaxial holes drilled and tapped,

radial holes drilled and tapped, reduced shaft diameter etc, we can machine for you,

and these special machines are finished after heat treatment and hard chromic so that ensure the precision of product.

Send us your detailed sketch or blue print for propmt quotation and action, you should be satisfied with our service.

Company Profile

HangZhou City CZPT Bearing Co., Ltd. is a professional manufacturer of linear motion products with many years’ experience. We are specialized in the producing linear shaft, linear guides, ball screws, linear bearings, linear CZPT blocks, ball screw end supports, linear rails, cam followers with good quality and competitive price. Our company is located in HangZhou city, ZHangZhoug province, close to HangZhou port and HangZhou city.

Our products are widely used in precise machines, fitness equipment, printing machines, packing machines, medical and food machines, textile machinery and other machines and supplementary equipment. Our products sell well in North America, West Europe, Australia, Southeast Asia, Middle East, South America and other regions.

After Sales Service

Our Quality:

Quality is the life . We use only the best quality material to ensure the standard of our product range is of the highest caliber.All products we sold out are strictly selected and tested by our QC department.

Warranty:

All products may have problem after used by a period of time. We provide 1 year warranty for all products.

Payment:

We accept payment via TT (Bank transfer), Paypal,Western Union, and Money Gram.

We accept bank transfer for large orders. For small order, you’d better pay via Paypal,Western union or Money Gram

Shipping:

We offer as many shipping options as possible, including DHL, UPS, TNT, FEDEX and EMS, Airfreight and by Sea.

FAQ

1. Are you factory or trading company?

We are professional manufacturer with most competitive price and high quality, 15 year’s experience.

2.What’s your product range?

We are specialized in producing linear shafts, linear bearings, linear guides, linear rails, ball screws,cam follower and other linear motion units.

3.Do you offer OEM&ODM services?

Yes, OEM, ODM is welcomed

4.How Can I get some samples?

We are honored to offer samples. You are requested to pay the shipping cost and some samples cost.

5.What does your factory do about quality control?

We uphold the tenet of “Quality is the future, we have passed ISO9001 certification, and we have strict procedures to control quality.

6. How can I get a quotation?

You can send quotation below or email to us. you can contact dirrectly with us through TM or WhatsApp,Skype as you like.Call any time if you are urgent.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | G6 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

What advancements in screw jack technology have improved efficiency and reliability?

Advancements in screw jack technology have led to significant improvements in efficiency and reliability. Here are some key advancements that have contributed to these improvements:

- High-Efficiency Ball Screws: Traditional screw jacks often used trapezoidal or square threads, which had relatively lower efficiency due to higher friction. However, the introduction of high-efficiency ball screws in screw jack designs has greatly improved efficiency. Ball screws offer low friction and higher efficiency, resulting in reduced power consumption and improved overall system efficiency.

- Improved Lubrication Systems: Proper lubrication is crucial for the smooth operation and longevity of screw jacks. Advancements in lubrication systems, such as the use of self-lubricating materials, improved lubricants, and better sealing mechanisms, have enhanced the reliability and maintenance intervals of screw jacks. These advancements minimize wear, reduce friction, and ensure consistent performance over extended periods.

- Materials and Coatings: The use of advanced materials and coatings has significantly improved the durability and reliability of screw jacks. Components made from high-strength alloys, such as stainless steel or hardened steel, can withstand higher loads and resist wear. Additionally, coatings like zinc plating or epoxy coatings provide corrosion resistance, extending the lifespan of screw jacks in challenging environments.

- Integrated Sensors and Feedback Systems: Integration of sensors and feedback systems in screw jacks has improved their reliability and control. Position sensors, load sensors, and torque sensors can be integrated into screw jacks to provide real-time feedback and monitoring. This enables precise positioning, load measurement, and the ability to detect and respond to abnormal operating conditions, ensuring safe and reliable operation.

- Automation and Control Integration: The integration of screw jacks with advanced automation and control systems has improved efficiency and reliability. Motorized screw jacks can be integrated with programmable logic controllers (PLCs) or computer numerical control (CNC) systems, enabling precise and synchronized movements, remote operation, and automation. This integration minimizes human error, enhances repeatability, and optimizes the overall efficiency of screw jack systems.

- Design Optimization: Advancements in computer-aided design (CAD) and simulation tools have allowed for the optimization of screw jack designs. Finite element analysis (FEA) and virtual prototyping enable the evaluation and refinement of various design parameters, resulting in improved load-bearing capabilities, reduced weight, and enhanced structural integrity. These design optimizations contribute to increased efficiency and reliability.

These advancements in screw jack technology have collectively improved efficiency, reliability, and overall performance. Manufacturers continue to innovate and refine screw jack designs to meet the evolving needs of various industries, ensuring that screw jacks remain a reliable and efficient solution for lifting and adjusting loads.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

Can screw jacks be customized for specific tasks like stage or platform adjustments?

Yes, screw jacks can be customized for specific tasks such as stage or platform adjustments. Customization allows screw jacks to meet the unique requirements of different applications, providing precise and reliable positioning and lifting solutions. Here’s how screw jacks can be customized for specific tasks:

- Load Capacity: Screw jacks can be customized to handle various load capacities. The load capacity of a screw jack is determined by factors such as the size and strength of the screw and the material used in its construction. By selecting the appropriate components and dimensions, screw jacks can be tailored to support the specific weight requirements of stages, platforms, or other equipment.

- Stroke Length: The stroke length of a screw jack refers to the distance it can extend or retract. By adjusting the length of the screw, the stroke length can be customized to accommodate the desired range of movement for stage or platform adjustments. This ensures that the screw jack can achieve the required height or position adjustments accurately.

- Speed: Depending on the application, the speed of stage or platform adjustments may be a critical factor. Screw jacks can be customized to provide different operating speeds by selecting the appropriate gear ratio or motor speed. This customization allows for efficient and precise adjustments, whether they need to be fast or slow.

- Mounting Options: Screw jacks can be customized to offer various mounting options to suit specific applications. Different types of mounting brackets, flanges, or couplings can be provided to ensure easy integration with existing structures or equipment. Customized mounting options simplify the installation process and enhance the overall functionality of the stage or platform adjustment system.

- Control Mechanism: Screw jacks can be customized with different control mechanisms to suit specific requirements. Manual control options, such as handwheels or crank handles, can be provided for simpler applications. For more complex systems or automated processes, electric or hydraulic motor-driven options can be implemented. Customized control mechanisms enable convenient and efficient operation of the screw jacks.

- Environmental Considerations: Depending on the operating environment, screw jacks can be customized with appropriate materials, coatings, or seals to ensure durability and performance. For example, in corrosive or outdoor settings, stainless steel or protective coatings can be applied to prevent degradation. Customization for environmental considerations enhances the longevity and reliability of screw jacks in specific tasks like stage or platform adjustments.

By offering customizable load capacities, stroke lengths, speeds, mounting options, control mechanisms, and environmental considerations, screw jacks can be tailored to meet the specific requirements of stage or platform adjustments. Customization ensures precise and reliable performance, contributing to the smooth operation of stages, platforms, or other equipment in various applications.

editor by CX 2024-04-09

China Good quality Factory Direct Supply High Frequency Induction Hardening Machine for Quenching The Shaft Metals threaded bearing shaft

Product Description

Factory direct supply High frequency induction hardening machine for quenching the shaft metals:

Advantage:

1 More than 21 years experience, high quality, stable performance

2 ISO, CE, SGS certificated

3 PLC OR CNC quenching machine line, automatic program, save workers, imporve work efficient.

Features:

1. The lifting by the Servo motor, position control by the digital input, precision of 0.1mm, wider rang of speed adjustment. The screw lift used in precision ball screw, leading column used in circular column structure, All pillar are thermal refining 45#. Hard chromium plated, No-rust, No-distortion, to ensure durable of machine.

2. Limit lift of machine position by the inductive proximity switches control. Machine with safe buffering.

3. By the mechanical type, abandoned the heavy, large hydraulic systems, To avoid leakage of hydraulic components and reduced accuracy caused by changes brought about by the oil temperature rate of change of equipment operation.

At the same time, reduce the equipment of use for requirements, Machine are use more simple smaller, operation and maintenance more convenience, rarely needs servicing.

4. Use motor control lift on the top. Can according the length of work piece to adjustment. Can be used clomping table, to ensure normal rotation of work piece.

5. The rotating speed can be adjusted digital on control panel. To meet the needs of high-precision adjustment. According to the size of work piece and requirement of quenching process. Can realiachieve the best quenching effect and quality of the work piece.

6. According to operator who can be used to adjust the position of cabinet. So that will be easy handle and work with great efficiency.

7. Work piece rotation by the S, wider rang of speed adjustment, clear and easy; Drive motor is located above the quench, to prevent the motor damp.

8. Quenched by cooling spray, at below of machine have 300mm high water tank. Without need another water tank. Reduce the installation work.

9. Easy disassembly and convenient maintenance. The main components of electronic products used in ZheJiang , long life, low maintenance cost. System uses the full English menu, intuitive interface, easy operation. The CNC/PLC panel can direct input and control quenching time, vertical speed, rotation speed etc. Can store a variety of procedures, easy to calls, especially for multi-stage, variable speed requirements and complex process etc

| Model | ORD-1500MM |

| Work postion | 1 |

| The larggest length of the clamping workpiece | 1550mm |

| The max quenching length | 1500mm |

| the max turning diameter | 600mm |

| workpiece rotation speed | 20~180r/min |

| Quenching feeding speed | 6~3000mm/min |

| Workpiece down fast speed | 400mm/min |

| the max bear weight | 500KG |

| positioning accuracy of the quenching machine line | PLC /CNC Control |

| quenching machine line operation way | Movement Quenching/Soak Quenching |

| quenching speed adjustable | stepless adjustable |

| workpiece rotational speed adjustable | stepless adjustable |

| Water cooling sytem | spray water or spray liquid |

Pre-sale service:

1. recommend the most suitable machine for customers, according to their requirements.

2. Inquiry and consulting support.

3. Sample testing support.

4. View our Factory.

In-sale service:

1. Strictly manufacture the machine, according to relevant technical standards.

2. Take run test, according to relevant equipment test run regulations.

3. Strictly check up the machine, before delivery

4. Delivery on time.

After-sale service:

1. Warranty time: Within 18 months from the date of delivering, 12months from date of receiving.

2. Within warranty all parts are free for customer, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, We shall provide replacement parts after detecting the faults.

3. If any big quality problems occurs out of the guarantee period, we will send maintenance

technician to provide visiting service after checking with the customer and charge for a favorable price.

5. We will provide a lifetime cost price to the buyer with the materials and spare parts used in system operation, equipment maintenance.

6. The above mentioned are only basic aftersale service requirements,we will make more promises related to quality assurance and operation guarantee. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Within 24 Hours Response. Lifetime Service |

|---|---|

| Warranty: | 1 Year |

| Type: | Induction Heating Machine |

| Certification: | CE |

| Structure: | Vertical Type |

| Brand: | Ord |

| Customization: |

Available

| Customized Request |

|---|

Can screw jacks be adapted for use in both indoor and outdoor environments?

Yes, screw jacks can be adapted for use in both indoor and outdoor environments. They are versatile mechanical devices that can be designed and manufactured to withstand various environmental conditions. Here’s how screw jacks can be adapted for both indoor and outdoor use:

- Enclosure and Sealing: When screw jacks are intended for outdoor use, they can be equipped with enclosures and sealing mechanisms to protect the internal components from environmental factors such as moisture, dust, or debris. These enclosures are typically made from durable materials like stainless steel or corrosion-resistant coatings to ensure long-term protection.

- Corrosion Resistance: Outdoor environments often expose equipment to corrosive elements. To address this, screw jacks can be manufactured with corrosion-resistant materials or coatings. Stainless steel or zinc plating are commonly used to enhance the corrosion resistance of screw jacks, making them suitable for outdoor applications where exposure to moisture, humidity, or chemicals is expected.

- Weatherproofing: Screw jacks can be designed with weatherproofing features to resist environmental conditions such as rain, snow, or extreme temperatures. This may include seals, gaskets, or protective covers that prevent water or debris from entering the internal components, ensuring reliable operation in outdoor environments.

- UV Resistance: Outdoor applications often expose equipment to ultraviolet (UV) radiation from sunlight. Screw jacks can be manufactured using materials that are UV-resistant or incorporate UV-protective coatings. This helps prevent degradation or discoloration of the components due to prolonged exposure to sunlight.